Page 384 - Adsorbents fundamentals and applications

P. 384

NO X REMOVAL 369

100

a

80 b

c

d

e

NO Removal (%) 40

60

20

0

0 2 4 6 8 10

Time (h)

◦

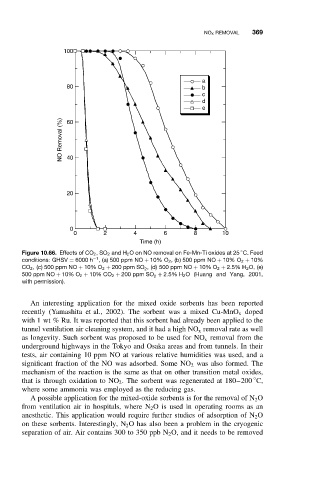

Figure 10.66. Effects of CO 2 ,SO 2 and H 2 O on NO removal on Fe-Mn-Ti oxides at 25 C. Feed

conditions: GHSV = 6000 h −1 , (a) 500 ppm NO + 10% O 2 , (b) 500 ppm NO + 10% O 2 + 10%

CO 2 , (c) 500 ppm NO + 10% O 2 + 200 ppm SO 2 , (d) 500 ppm NO + 10% O 2 + 2.5% H 2 O, (e)

500 ppm NO + 10% O 2 + 10% CO 2 + 200 ppm SO 2 + 2.5% H 2 O (Huang and Yang, 2001,

with permission).

An interesting application for the mixed oxide sorbents has been reported

recently (Yamashita et al., 2002). The sorbent was a mixed Cu-MnO x doped

with 1 wt % Ru. It was reported that this sorbent had already been applied to the

tunnel ventilation air cleaning system, and it had a high NO x removal rate as well

as longevity. Such sorbent was proposed to be used for NO x removal from the

underground highways in the Tokyo and Osaka areas and from tunnels. In their

tests, air containing 10 ppm NO at various relative humidities was used, and a

significant fraction of the NO was adsorbed. Some NO 2 was also formed. The

mechanism of the reaction is the same as that on other transition metal oxides,

◦

that is through oxidation to NO 2 . The sorbent was regenerated at 180–200 C,

where some ammonia was employed as the reducing gas.

A possible application for the mixed-oxide sorbents is for the removal of N 2 O

from ventilation air in hospitals, where N 2 O is used in operating rooms as an

anesthetic. This application would require further studies of adsorption of N 2 O

on these sorbents. Interestingly, N 2 O has also been a problem in the cryogenic

separation of air. Air contains 300 to 350 ppb N 2 O, and it needs to be removed