Page 115 - Advanced Gas Turbine Cycles

P. 115

88 Advanced gas turbine cycles

LOW s

T13

I

HEAT TRANSFERRED

OPTIMUM S

Maximum steam exit

temperature

STEAM / WATER

Minimum pinch point

temperature

HEAT TRANSFERRED difference

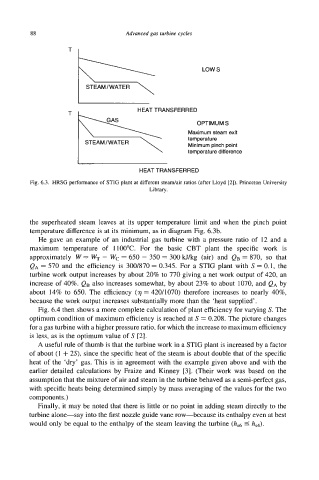

Fig. 6.3. HRSG performance of STIG plant at different steam/air ratios (after Lloyd [2]). Princeton University

Library.

the superheated steam leaves at its upper temperature limit and when the pinch point

temperature difference is at its minimum, as in diagram Fig. 6.3b.

He gave an example of an industrial gas turbine with a pressure ratio of 12 and a

maximum temperature of 1100°C. For the basic CBT plant the specific work is

approximately W = WT - Wc = 650 - 350 = 300 kJkg (air) and QB = 870, so that

QA = 570 and the efficiency is 300/870 = 0.345. For a STIG plant with S = 0.1, the

turbine work output increases by about 20% to 770 giving a net work output of 420, an

increase of 40%. QB also increases somewhat, by about 23% to about 1070, and QA by

about 14% to 650. The efficiency (7) = 420/1070) therefore increases to nearly 40%,

because the work output increases substantially more than the ‘heat supplied’.

Fig. 6.4 then shows a more complete calculation of plant efficiency for varying S. The

optimum condition of maximum efficiency is reached at S = 0.208. The picture changes

for a gas turbine with a higher pressure ratio, for which the increase to maximum efficiency

is less, as is the optimum value of S [2].

A useful rule of thumb is that the turbine work in a STIG plant is increased by a factor

of about (1 + 2S), since the specific heat of the steam is about double that of the specific

heat of the ‘dry’ gas. This is in agreement with the example given above and with the

earlier detailed calculations by Fraize and Kinney [3]. (Their work was based on the

assumption that the mixture of air and steam in the turbine behaved as a semi-perfect gas,

with specific heats being determined simply by mass averaging of the values for the two

components.)

Finally, it may be noted that there is little or no point in adding steam directly to the

turbine alone-say into the first nozzle guide vane row-because its enthalpy even at best

would only be equal to the enthalpy of the steam leaving the turbine (hs6 5 h&).