Page 435 - Advanced thermodynamics for engineers

P. 435

18.1 LIQUEFACTION BY COOLING – METHOD (I) 425

between the top and bottom temperatures is related to the difference between the pressures. To achieve

a low temperature, it is necessary to reduce the evaporator pressure, and this will increase the specific

volume of the working fluid and hence the size of the evaporator. The large temperature difference will

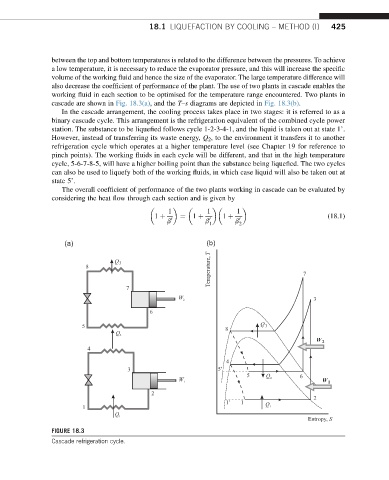

also decrease the coefficient of performance of the plant. The use of two plants in cascade enables the

working fluid in each section to be optimised for the temperature range encountered. Two plants in

cascade are shown in Fig. 18.3(a), and the T–s diagrams are depicted in Fig. 18.3(b).

In the cascade arrangement, the cooling process takes place in two stages: it is referred to as a

binary cascade cycle. This arrangement is the refrigeration equivalent of the combined cycle power

station. The substance to be liquefied follows cycle 1-2-3-4-1, and the liquid is taken out at state 1’.

However, instead of transferring its waste energy, Q 2 , to the environment it transfers it to another

refrigeration cycle which operates at a higher temperature level (see Chapter 19 for reference to

pinch points). The working fluids in each cycle will be different, and that in the high temperature

cycle, 5-6-7-8-5, will have a higher boiling point than the substance being liquefied. The two cycles

canalsobeusedtoliquefy both ofthe workingfluids, inwhich case liquidwill also be takenout at

state 5’.

The overall coefficient of performance of the two plants working in cascade can be evaluated by

considering the heat flow through each section and is given by

1 1 1

1 þ ¼ 1 þ 1 þ (18.1)

b 0 b 0 1 b 0 2

(a) (b)

Temperature, T 7

Q 3

8

7

W 3

6

5 8 Q 3

Q

W 2

4

4

3 5'

5 Q 6

W W 1

2

2

1' 1 Q

1

Q

Entropy, S

FIGURE 18.3

Cascade refrigeration cycle.