Page 53 - Advances in Biomechanics and Tissue Regeneration

P. 53

3.3 DESIGN METHODOLOGY 47

The geometrical pattern adopted allows the manufacturing of the initial shape performed by the cutting laser tech-

nique, creating a longitudinal nonhomogeneous distribution of grooves on the tube surface, with a given width and

length. In the next step, the slotted tube is expanded until it reaches the stent configuration. The chosen design allows a

precision manufacturing process for obtaining controlled custom designs for each pathology and patient in an efficient

and economically viable manner.

The geometric typology proposed is a tube-based stent with closed diamond-shaped cells (Palmaz-Schatz type),

which correspond to the basic geometry module used by the authors to design and manufacture a prototype colonic stent

[48, 53]. In a previous comparative analysis of stents for the treatment of colorectal obstruction [48] and by means of

experimental animal testing [54], it was shown that stents based on closed cells with arms joined by rigid nodes develop

higher radial force response, necessary for reopening occlusive colonic strictures where greater strength is required.

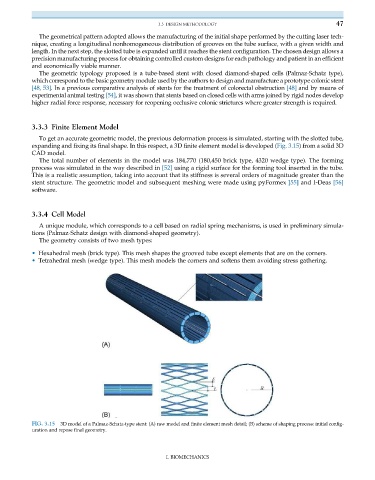

3.3.3 Finite Element Model

To get an accurate geometric model, the previous deformation process is simulated, starting with the slotted tube,

expanding and fixing its final shape. In this respect, a 3D finite element model is developed (Fig. 3.15) from a solid 3D

CAD model.

The total number of elements in the model was 184,770 (180,450 brick type, 4320 wedge type). The forming

process was simulated in the way described in [52] using a rigid surface for the forming tool inserted in the tube.

This is a realistic assumption, taking into account that its stiffness is several orders of magnitude greater than the

stent structure. The geometric model and subsequent meshing were made using pyFormex [55] and I-Deas [56]

software.

3.3.4 Cell Model

A unique module, which corresponds to a cell based on radial spring mechanisms, is used in preliminary simula-

tions (Palmaz-Schatz design with diamond-shaped geometry).

The geometry consists of two mesh types:

• Hexahedral mesh (brick type). This mesh shapes the grooved tube except elements that are on the corners.

• Tetrahedral mesh (wedge type). This mesh models the corners and softens them avoiding stress gathering.

FIG. 3.15 3D model of a Palmaz-Schatz-type stent: (A) raw model and finite element mesh detail; (B) scheme of shaping process: initial config-

uration and repose final geometry.

I. BIOMECHANICS