Page 330 - Air Pollution Control Engineering

P. 330

06_chap_wang.qxd 05/05/2004 4:10 pm Page 309

Condensation 309

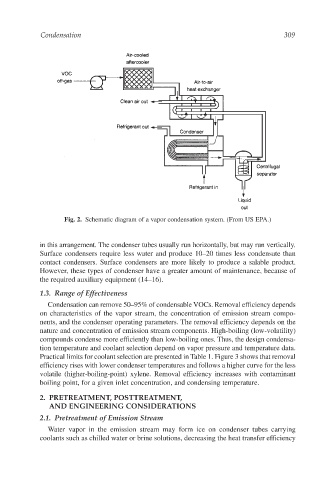

Fig. 2. Schematic diagram of a vapor condensation system. (From US EPA.)

in this arrangement. The condenser tubes usually run horizontally, but may run vertically.

Surface condensers require less water and produce 10–20 times less condensate than

contact condensers. Surface condensers are more likely to produce a salable product.

However, these types of condenser have a greater amount of maintenance, because of

the required auxiliary equipment (14–16).

1.3. Range of Effectiveness

Condensation can remove 50–95% of condensable VOCs. Removal efficiency depends

on characteristics of the vapor stream, the concentration of emission stream compo-

nents, and the condenser operating parameters. The removal efficiency depends on the

nature and concentration of emission stream components. High-boiling (low-volatility)

compounds condense more efficiently than low-boiling ones. Thus, the design condensa-

tion temperature and coolant selection depend on vapor pressure and temperature data.

Practical limits for coolant selection are presented in Table 1. Figure 3 shows that removal

efficiency rises with lower condenser temperatures and follows a higher curve for the less

volatile (higher-boiling-point) xylene. Removal efficiency increases with contaminant

boiling point, for a given inlet concentration, and condensing temperature.

2. PRETREATMENT, POSTTREATMENT,

AND ENGINEERING CONSIDERATIONS

2.1. Pretreatment of Emission Stream

Water vapor in the emission stream may form ice on condenser tubes carrying

coolants such as chilled water or brine solutions, decreasing the heat transfer efficiency