Page 295 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 295

272 9 In-combustion Air Emission Control

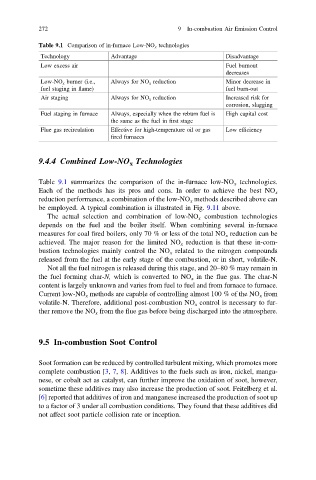

Table 9.1 Comparison of in-furnace Low-NO x technologies

Technology Advantage Disadvantage

Low excess air Fuel burnout

decreases

Low-NO x burner (i.e., Always for NO x reduction Minor decrease in

fuel staging in flame) fuel burn-out

Air staging Always for NO x reduction Increased risk for

corrosion, slagging

Fuel staging in furnace Always, especially when the reburn fuel is High capital cost

the same as the fuel in first stage

Flue gas recirculation Effective for high-temperature oil or gas Low efficiency

fired furnaces

9.4.4 Combined Low-NO Technologies

x

Table 9.1 summarizes the comparison of the in-furnace low-NO x technologies.

Each of the methods has its pros and cons. In order to achieve the best NO x

reduction performance, a combination of the low-NO x methods described above can

be employed. A typical combination is illustrated in Fig. 9.11 above.

The actual selection and combination of low-NO x combustion technologies

depends on the fuel and the boiler itself. When combining several in-furnace

measures for coal fired boilers, only 70 % or less of the total NO x reduction can be

achieved. The major reason for the limited NO x reduction is that these in-com-

bustion technologies mainly control the NO x related to the nitrogen compounds

released from the fuel at the early stage of the combustion, or in short, volatile-N.

Not all the fuel nitrogen is released during this stage, and 20–80 % may remain in

the fuel forming char-N, which is converted to NO x in the flue gas. The char-N

content is largely unknown and varies from fuel to fuel and from furnace to furnace.

Current low-NO x methods are capable of controlling almost 100 % of the NO x from

volatile-N. Therefore, additional post-combustion NO x control is necessary to fur-

ther remove the NO x from the flue gas before being discharged into the atmosphere.

9.5 In-combustion Soot Control

Soot formation can be reduced by controlled turbulent mixing, which promotes more

complete combustion [3, 7, 8]. Additives to the fuels such as iron, nickel, manga-

nese, or cobalt act as catalyst, can further improve the oxidation of soot, however,

sometime these additives may also increase the production of soot. Feitelberg et al.

[6] reported that additives of iron and manganese increased the production of soot up

to a factor of 3 under all combustion conditions. They found that these additives did

not affect soot particle collision rate or inception.