Page 117 - Air and gas Drilling Field Guide 3rd Edition

P. 117

108 CHAPTER 5 Compressors and Nitrogen Generators

1

2

5

3

4

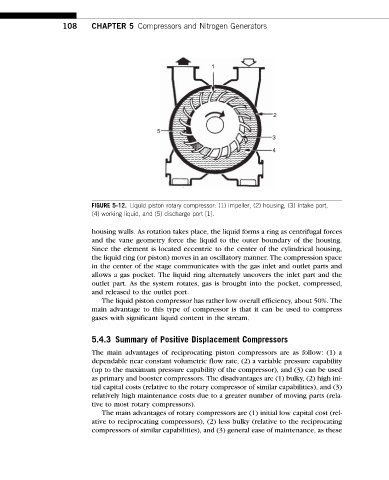

FIGURE 5-12. Liquid piston rotary compressor: (1) impeller, (2) housing, (3) intake port,

(4) working liquid, and (5) discharge port [1].

housing walls. As rotation takes place, the liquid forms a ring as centrifugal forces

and the vane geometry force the liquid to the outer boundary of the housing.

Since the element is located eccentric to the center of the cylindrical housing,

the liquid ring (or piston) moves in an oscillatory manner. The compression space

in the center of the stage communicates with the gas inlet and outlet parts and

allows a gas pocket. The liquid ring alternately uncovers the inlet part and the

outlet part. As the system rotates, gas is brought into the pocket, compressed,

and released to the outlet port.

The liquid piston compressor has rather low overall efficiency, about 50%. The

main advantage to this type of compressor is that it can be used to compress

gases with significant liquid content in the stream.

5.4.3 Summary of Positive Displacement Compressors

The main advantages of reciprocating piston compressors are as follow: (1) a

dependable near constant volumetric flow rate, (2) a variable pressure capability

(up to the maximum pressure capability of the compressor), and (3) can be used

as primary and booster compressors. The disadvantages are (1) bulky, (2) high ini-

tial capital costs (relative to the rotary compressor of similar capabilities), and (3)

relatively high maintenance costs due to a greater number of moving parts (rela-

tive to most rotary compressors).

The main advantages of rotary compressors are (1) initial low capital cost (rel-

ative to reciprocating compressors), (2) less bulky (relative to the reciprocating

compressors of similar capabilities), and (3) general ease of maintenance, as these