Page 113 - Air and gas Drilling Field Guide 3rd Edition

P. 113

104 CHAPTER 5 Compressors and Nitrogen Generators

The bottom pressure versus volumetric flow rate plot in Figure 5-9 shows the

typical situation when the back pressure on the outlet side of the compressor is

less than the built-in design output pressure. Under these conditions, the gas exit-

ing the compressor expands in the expansion tank and the initial portion of the

pipeline until the pressure is equal to the pipeline back pressure [1].

Rotary compressors can also be designed with two stages. Such compressors

are designed with nearly equal compression ratios for each stage (i.e., minimum

input power requirements). Thus, because the volumetric flow rate (in actual

cfm) is reduced from one stage to the next, the volume displacement of each

stage (its geometric size) is progressively smaller.

Rotary compressors are only used as primary compressors in drilling

operations.

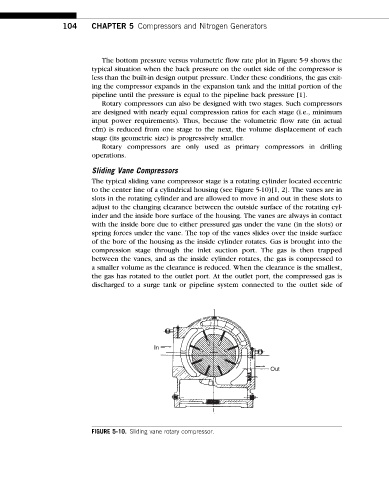

Sliding Vane Compressors

The typical sliding vane compressor stage is a rotating cylinder located eccentric

to the center line of a cylindrical housing (see Figure 5-10)[1, 2]. The vanes are in

slots in the rotating cylinder and are allowed to move in and out in these slots to

adjust to the changing clearance between the outside surface of the rotating cyl-

inder and the inside bore surface of the housing. The vanes are always in contact

with the inside bore due to either pressured gas under the vane (in the slots) or

spring forces under the vane. The top of the vanes slides over the inside surface

of the bore of the housing as the inside cylinder rotates. Gas is brought into the

compression stage through the inlet suction port. The gas is then trapped

between the vanes, and as the inside cylinder rotates, the gas is compressed to

a smaller volume as the clearance is reduced. When the clearance is the smallest,

the gas has rotated to the outlet port. At the outlet port, the compressed gas is

discharged to a surge tank or pipeline system connected to the outlet side of

In

Out

FIGURE 5-10. Sliding vane rotary compressor.