Page 108 - Air and gas Drilling Field Guide 3rd Edition

P. 108

5.3 Continuous Flow (Dynamic) Compressors 99

rather low, of the order of 2, there is little need for intercooling between each stage

(Figure 5-5 shows an intercooler after first three stages).

The centrifugal compressor must operate at rather high rotation speeds to be

efficient. Most commercial centrifugal compressors operate at speeds on the

order of 20,000 to 30,000 rpm. With such rotation speeds, very large volumes

of gas can be compressed with equipment having rather modest external dimen-

sions. Commercial centrifugal compressors can operate with volumetric flow

4 3

rates up to approximately 10 actual cfm (4.7 10 actual liters/sec) and with

overall multistage compression ratios up to about 20.

Centrifugal compressors are usually used in large processing plants and in

some pipeline applications. They can be operated with some small percentage

of liquid in the gas flow.

These machines are used principally to compress large volumetric flow rates

to rather modest pressures. Thus, their use is more applicable to the petroleum

refining and chemical processing industries.

More details regarding the centrifugal compressor can be found elsewhere

[2, 7–9].

5.3.2 Axial-Flow Compressors

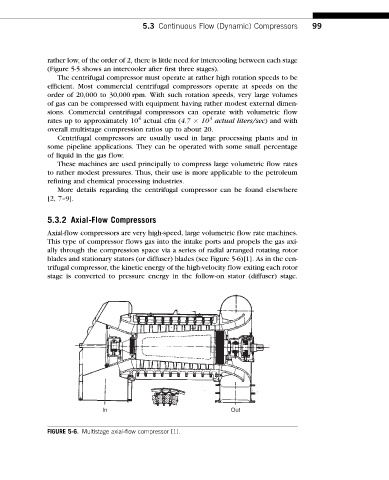

Axial-flow compressors are very high-speed, large volumetric flow rate machines.

This type of compressor flows gas into the intake ports and propels the gas axi-

ally through the compression space via a series of radial arranged rotating rotor

blades and stationary stators (or diffuser) blades (see Figure 5-6)[1]. As in the cen-

trifugal compressor, the kinetic energy of the high-velocity flow exiting each rotor

stage is converted to pressure energy in the follow-on stator (diffuser) stage.

In Out

FIGURE 5-6. Multistage axial-flow compressor [1].