Page 270 - Air and gas Drilling Field Guide 3rd Edition

P. 270

10.6 Conclusions 261

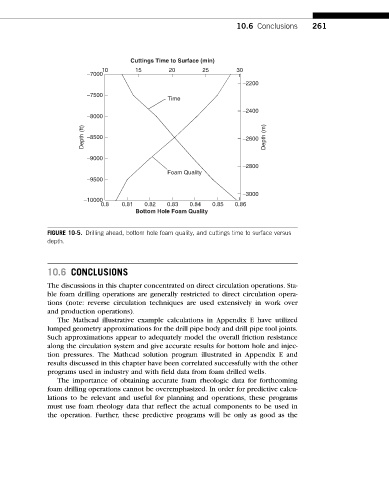

Cuttings Time to Surface (min)

10 15 20 25 30

−7000

−2200

−7500

Time

−2400

−8000

Depth (ft) −8500 −2600 Depth (m)

−9000

−2800

Foam Quality

−9500

−3000

−10000

0.8 0.81 0.82 0.83 0.84 0.85 0.86

Bottom Hole Foam Quality

FIGURE 10-5. Drilling ahead, bottom hole foam quality, and cuttings time to surface versus

depth.

10.6 CONCLUSIONS

The discussions in this chapter concentrated on direct circulation operations. Sta-

ble foam drilling operations are generally restricted to direct circulation opera-

tions (note: reverse circulation techniques are used extensively in work over

and production operations).

The Mathcad illustrative example calculations in Appendix E have utilized

lumped geometry approximations for the drill pipe body and drill pipe tool joints.

Such approximations appear to adequately model the overall friction resistance

along the circulation system and give accurate results for bottom hole and injec-

tion pressures. The Mathcad solution program illustrated in Appendix E and

results discussed in this chapter have been correlated successfully with the other

programs used in industry and with field data from foam drilled wells.

The importance of obtaining accurate foam rheologic data for forthcoming

foam drilling operations cannot be overemphasized. In order for predictive calcu-

lations to be relevant and useful for planning and operations, these programs

must use foam rheology data that reflect the actual components to be used in

the operation. Further, these predictive programs will be only as good as the