Page 266 - Air and gas Drilling Field Guide 3rd Edition

P. 266

10.5 Nonfriction and Friction Illustrative Examples 257

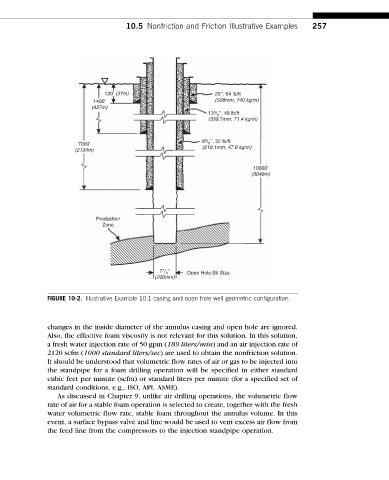

120’ (37m) 20’’, 94 lb/ft

1400’ (508mm, 140 kg/m)

(427m)

3

13 / ’’, 48 lb/ft

8

(339.7mm, 71.4 kg/m)

8 5 / ’’, 32 lb/ft

7000’ 8

(2134m) (219.1mm, 47.6 kg/m)

10000’

(3048m)

Production

Zone

7 7 / ’’ Open Hole Bit Size

8

(200mm)

FIGURE 10-2. Illustrative Example 10.1 casing and open hole well geometric configuration.

changes in the inside diameter of the annulus casing and open hole are ignored.

Also, the effective foam viscosity is not relevant for this solution. In this solution,

a fresh water injection rate of 50 gpm (189 liters/min) and an air injection rate of

2120 scfm (1000 standard liters/sec) are used to obtain the nonfriction solution.

It should be understood that volumetric flow rates of air or gas to be injected into

the standpipe for a foam drilling operation will be specified in either standard

cubic feet per minute (scfm) or standard liters per minute (for a specified set of

standard conditions, e.g., ISO, API, ASME).

As discussed in Chapter 9, unlike air drilling operations, the volumetric flow

rate of air for a stable foam operation is selected to create, together with the fresh

water volumetric flow rate, stable foam throughout the annulus volume. In this

event, a surface bypass valve and line would be used to vent excess air flow from

the feed line from the compressors to the injection standpipe operation.