Page 60 - Air and gas Drilling Field Guide 3rd Edition

P. 60

3.3 Wellhead Equipment 51

Packer Inserts

Bore of Top

Quick-Release

Access Flaps Top

Outer Cylinder

Lock-Down

Locking Grooves

in Body

Packer

Vent

Donut

Opening Side of

Pusher Plate

Piston

Closing Side of

Piston

Opening Closing Hydraulic Ports

Hydraulic Ports

SD 203-03

Operating Piston

Vent

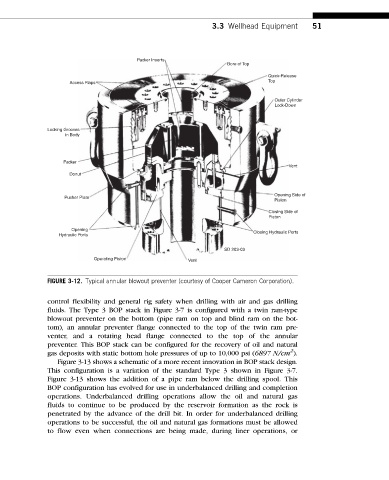

FIGURE 3-12. Typical annular blowout preventer (courtesy of Cooper Cameron Corporation).

control flexibility and general rig safety when drilling with air and gas drilling

fluids. The Type 3 BOP stack in Figure 3-7 is configured with a twin ram-type

blowout preventer on the bottom (pipe ram on top and blind ram on the bot-

tom), an annular preventer flange connected to the top of the twin ram pre-

venter, and a rotating head flange connected to the top of the annular

preventer. This BOP stack can be configured for the recovery of oil and natural

2

gas deposits with static bottom hole pressures of up to 10,000 psi (6897 N/cm ).

Figure 3-13 shows a schematic of a more recent innovation in BOP stack design.

This configuration is a variation of the standard Type 3 shown in Figure 3-7.

Figure 3-13 shows the addition of a pipe ram below the drilling spool. This

BOP configuration has evolved for use in underbalanced drilling and completion

operations. Underbalanced drilling operations allow the oil and natural gas

fluids to continue to be produced by the reservoir formation as the rock is

penetrated by the advance of the drill bit. In order for underbalanced drilling

operations to be successful, the oil and natural gas formations must be allowed

to flow even when connections are being made, during liner operations, or