Page 61 - Air and gas Drilling Field Guide 3rd Edition

P. 61

52 CHAPTER 3 Surface Equipment

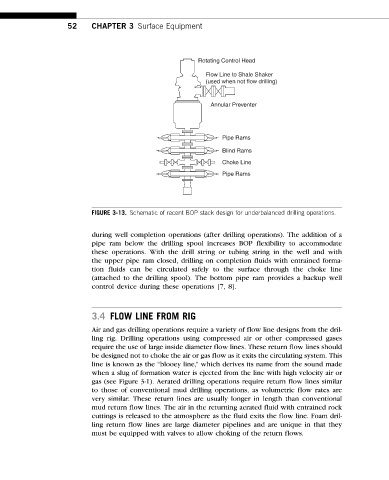

Rotating Control Head

Flow Line to Shale Shaker

(used when not flow drilling)

Annular Preventer

Pipe Rams

Blind Rams

Choke Line

Pipe Rams

FIGURE 3-13. Schematic of recent BOP stack design for underbalanced drilling operations.

during well completion operations (after drilling operations). The addition of a

pipe ram below the drilling spool increases BOP flexibility to accommodate

these operations. With the drill string or tubing string in the well and with

the upper pipe ram closed, drilling on completion fluids with entrained forma-

tion fluids can be circulated safely to the surface through the choke line

(attached to the drilling spool). The bottom pipe ram provides a backup well

control device during these operations [7, 8].

3.4 FLOW LINE FROM RIG

Air and gas drilling operations require a variety of flow line designs from the dril-

ling rig. Drilling operations using compressed air or other compressed gases

require the use of large inside diameter flow lines. These return flow lines should

be designed not to choke the air or gas flow as it exits the circulating system. This

line is known as the “blooey line,” which derives its name from the sound made

when a slug of formation water is ejected from the line with high velocity air or

gas (see Figure 3-1). Aerated drilling operations require return flow lines similar

to those of conventional mud drilling operations, as volumetric flow rates are

very similar. These return lines are usually longer in length than conventional

mud return flow lines. The air in the returning aerated fluid with entrained rock

cuttings is released to the atmosphere as the fluid exits the flow line. Foam dril-

ling return flow lines are large diameter pipelines and are unique in that they

must be equipped with valves to allow choking of the return flows.