Page 170 - An Introduction to Microelectromechanical Systems Engineering

P. 170

Fiber-Optic Communication Devices 149

reflectivity into the cavity. If Λ is the periodicity of a simple grating and n’ is the dif-

ference in indices of refraction of the materials bounding the grating, then the center

wavelength of the grating in free space is Λ/2n' [25]. For a grating centered at 1,550

nm in InP and InGaAsP (n’ 0.2), the required periodicity is approximately 0.6 µm,

necessitating fabrication using high-resolution lithographic tools such as an electron

beam. The dependence of optical gain and index of refraction on temperature

results in the lasing wavelength increasing with temperature at the rate of 0.12

nm/ºC over the range 20º to 80ºC. This is why semiconductor lasers include a TEC

device to control temperature and wavelength.

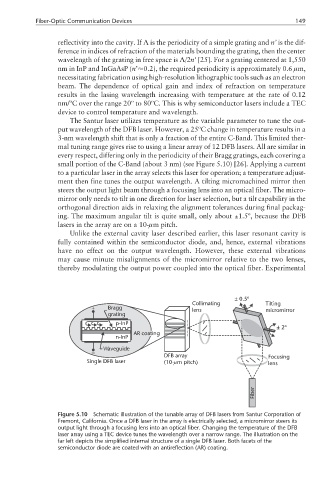

The Santur laser utilizes temperature as the variable parameter to tune the out-

put wavelength of the DFB laser. However, a 25ºC change in temperature results in a

3-nm wavelength shift that is only a fraction of the entire C-Band. This limited ther-

mal tuning range gives rise to using a linear array of 12 DFB lasers. All are similar in

every respect, differing only in the periodicity of their Bragg gratings, each covering a

small portion of the C-Band (about 3 nm) (see Figure 5.10) [26]. Applying a current

to a particular laser in the array selects this laser for operation; a temperature adjust-

ment then fine tunes the output wavelength. A tilting micromachined mirror then

steers the output light beam through a focusing lens into an optical fiber. The micro-

mirror only needs to tilt in one direction for laser selection, but a tilt capability in the

orthogonal direction aids in relaxing the alignment tolerances during final packag-

ing. The maximum angular tilt is quite small, only about ±1.5º, because the DFB

lasers in the array are on a 10-µm pitch.

Unlike the external cavity laser described earlier, this laser resonant cavity is

fully contained within the semiconductor diode, and, hence, external vibrations

have no effect on the output wavelength. However, these external vibrations

may cause minute misalignments of the micromirror relative to the two lenses,

thereby modulating the output power coupled into the optical fiber. Experimental

± 0.5º

Collimating Tilting

+ Bragg lens micromirror

grating

p-InP

±2º

AR coating

n-InP

Waveguide

DFB array Focusing

Single DFB laser (10- m pitch) lens

µ

Fiber

Figure 5.10 Schematic illustration of the tunable array of DFB lasers from Santur Corporation of

Fremont, California. Once a DFB laser in the array is electrically selected, a micromirror steers its

output light through a focusing lens into an optical fiber. Changing the temperature of the DFB

laser array using a TEC device tunes the wavelength over a narrow range. The illustration on the

far left depicts the simplified internal structure of a single DFB laser. Both facets of the

semiconductor diode are coated with an antireflection (AR) coating.