Page 214 - An Introduction to Microelectromechanical Systems Engineering

P. 214

Passive Electrical Components: Capacitors and Inductors 193

bulk-micromachined counterparts, but they have a nonlinear response to the tun-

ing voltage and smaller tuning ranges. The quality factor and self-resonance fre-

quency vary with the design.

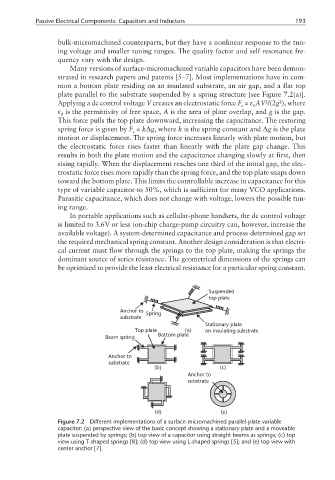

Many versions of surface-micromachined variable capacitors have been demon-

strated in research papers and patents [5–7]. Most implementations have in com-

mon a bottom plate residing on an insulated substrate, an air gap, and a flat top

plate parallel to the substrate suspended by a spring structure [see Figure 7.2(a)].

2

2

Applying a dc control voltage V creates an electrostatic force F = ε AV /(2g ), where

e 0

ε is the permittivity of free space, A is the area of plate overlap, and g is the gap.

0

This force pulls the top plate downward, increasing the capacitance. The restoring

spring force is given by F = k∆g, where k is the spring constant and ∆g is the plate

s

motion or displacement. The spring force increases linearly with plate motion, but

the electrostatic force rises faster than linearly with the plate gap change. This

results in both the plate motion and the capacitance changing slowly at first, then

rising rapidly. When the displacement reaches one third of the initial gap, the elec-

trostatic force rises more rapidly than the spring force, and the top plate snaps down

toward the bottom plate. This limits the controllable increase in capacitance for this

type of variable capacitor to 50%, which is sufficient for many VCO applications.

Parasitic capacitance, which does not change with voltage, lowers the possible tun-

ing range.

In portable applications such as cellular-phone handsets, the dc control voltage

is limited to 3.6V or less (on-chip charge-pump circuitry can, however, increase the

available voltage). A system-determined capacitance and process-determined gap set

the required mechanical spring constant. Another design consideration is that electri-

cal current must flow through the springs to the top plate, making the springs the

dominant source of series resistance. The geometrical dimensions of the springs can

be optimized to provide the least electrical resistance for a particular spring constant.

Suspended

top plate

Anchor to Spring

substrate

Stationary plate

Top plate (a) on insulating substrate

Bottom plate

Beam spring

Anchor to

substrate

(b) (c)

Anchor to

substrate

(d) (e)

Figure 7.2 Different implementations of a surface-micromachined parallel-plate variable

capacitor: (a) perspective view of the basic concept showing a stationary plate and a moveable

plate suspended by springs; (b) top view of a capacitor using straight beams as springs; (c) top

view using T-shaped springs [8]; (d) top view using L-shaped springs [5]; and (e) top view with

center anchor [7].