Page 38 - An Introduction to Microelectromechanical Systems Engineering

P. 38

Silicon-Compatible Material System 17

Secondary flat No secondary flat

(100) n-type flat (100) p-type (111) n-type (111) p-type

Secondary 90° 45°

Primary flat Secondary flat Primary flat

Primary flat

Primary flat

(a)

(100) plane (010) plane

(110) plane

z, [001] (001) plane

y, [010]

x, [100]

[110] direction

45 º

(110)

(b)

[001] (111)

[010] Surface

is (001)

(111) (111)

(111)

[100]

Flat is along [110] direction

(c)

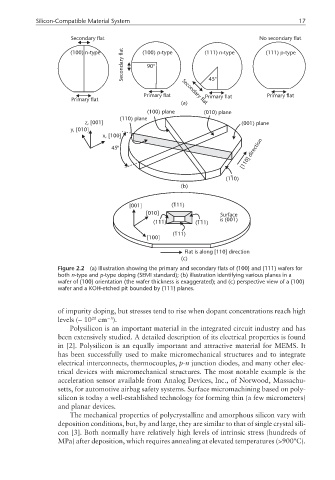

Figure 2.2 (a) Illustration showing the primary and secondary flats of {100} and {111} wafers for

both n-type and p-type doping (SEMI standard); (b) illustration identifying various planes in a

wafer of {100} orientation (the wafer thickness is exaggerated); and (c) perspective view of a {100}

wafer and a KOH-etched pit bounded by {111} planes.

of impurity doping, but stresses tend to rise when dopant concentrations reach high

levels (~ 10 cm ).

20

−3

Polysilicon is an important material in the integrated circuit industry and has

been extensively studied. A detailed description of its electrical properties is found

in [2]. Polysilicon is an equally important and attractive material for MEMS. It

has been successfully used to make micromechanical structures and to integrate

electrical interconnects, thermocouples, p-n junction diodes, and many other elec-

trical devices with micromechanical structures. The most notable example is the

acceleration sensor available from Analog Devices, Inc., of Norwood, Massachu-

setts, for automotive airbag safety systems. Surface micromachining based on poly-

silicon is today a well-established technology for forming thin (a few micrometers)

and planar devices.

The mechanical properties of polycrystalline and amorphous silicon vary with

deposition conditions, but, by and large, they are similar to that of single crystal sili-

con [3]. Both normally have relatively high levels of intrinsic stress (hundreds of

MPa) after deposition, which requires annealing at elevated temperatures (>900ºC).