Page 128 - Analysis and Design of Machine Elements

P. 128

Analysis and Design of Machine Elements

106

(a) (b) (c)

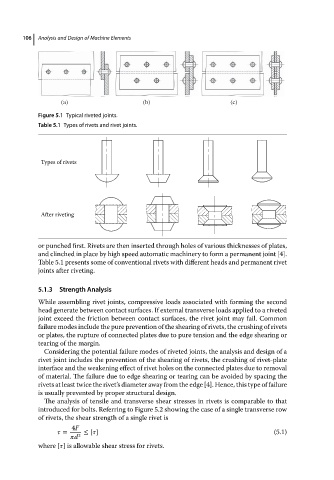

Figure 5.1 Typical riveted joints.

Table 5.1 Types of rivets and rivet joints.

Types of rivets

After riveting

or punched first. Rivets are then inserted through holes of various thicknesses of plates,

and clinched in place by high speed automatic machinery to form a permanent joint [4].

Table 5.1 presents some of conventional rivets with different heads and permanent rivet

joints after riveting.

5.1.3 Strength Analysis

While assembling rivet joints, compressive loads associated with forming the second

head generate between contact surfaces. If external transverse loads applied to a riveted

joint exceed the friction between contact surfaces, the rivet joint may fail. Common

failure modes include the pure prevention of the shearing of rivets, the crushing of rivets

or plates, the rupture of connected plates due to pure tension and the edge shearing or

tearing of the margin.

Considering the potential failure modes of riveted joints, the analysis and design of a

rivet joint includes the prevention of the shearing of rivets, the crushing of rivet-plate

interface and the weakening effect of rivet holes on the connected plates due to removal

of material. The failure due to edge shearing or tearing can be avoided by spacing the

rivets at least twice the rivet’s diameter away from the edge [4]. Hence, this type of failure

is usually prevented by proper structural design.

The analysis of tensile and transverse shear stresses in rivets is comparable to that

introduced for bolts. Referring to Figure 5.2 showing the case of a single transverse row

of rivets, the shear strength of a single rivet is

4F

= ≤ [ ] (5.1)

d 2

where [ ] is allowable shear stress for rivets.