Page 132 - Analysis and Design of Machine Elements

P. 132

Analysis and Design of Machine Elements

110

power and oil industries. Welded joints are superior to riveted joints for strong strength,

light weight and low cost. Nevertheless, welding may generate unacceptable residual

stresses and thermal distortions if the welding process is not properly controlled.

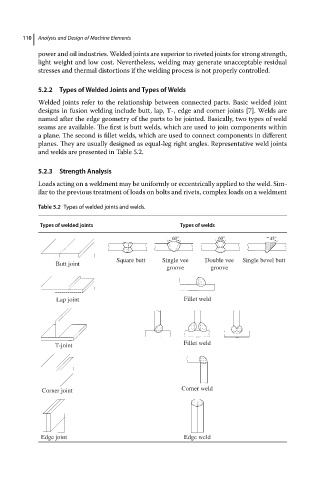

5.2.2 Types of Welded Joints and Types of Welds

Welded joints refer to the relationship between connected parts. Basic welded joint

designs in fusion welding include butt, lap, T-, edge and corner joints [7]. Welds are

named after the edge geometry of the parts to be jointed. Basically, two types of weld

seams are available. The first is butt welds, which are used to join components within

a plane. The second is fillet welds, which are used to connect components in different

planes. They are usually designed as equal-leg right angles. Representative weld joints

and welds are presented in Table 5.2.

5.2.3 Strength Analysis

Loads acting on a weldment may be uniformly or eccentrically applied to the weld. Sim-

ilar to the previous treatment of loads on bolts and rivets, complex loads on a weldment

Table 5.2 Types of welded joints and welds.

Typesofweldedjoints Types of welds

60° 60° 45°

Square butt Single vee Double vee Single bevel butt

Butt joint

groove groove

Lap joint Fillet weld

T-joint Fillet weld

Corner joint Corner weld

Edge joint Edge weld