Page 227 - Analysis and Design of Machine Elements

P. 227

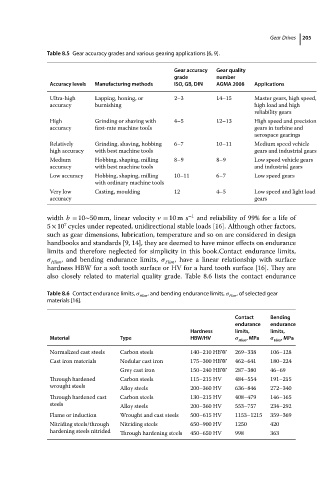

Table 8.5 Gear accuracy grades and various gearing applications [6, 9]. Gear Drives 205

Gear accuracy Gear quality

grade number

Accuracy levels Manufacturing methods ISO, GB, DIN AGMA 2008 Applications

Ultra-high Lapping, honing, or 2–3 14–15 Master gears, high speed,

accuracy burnishing high load and high

reliability gears

High Grinding or shaving with 4–5 12–13 High speed and precision

accuracy first-rate machine tools gears in turbine and

aerospace gearings

Relatively Grinding, shaving, hobbing 6–7 10–11 Medium speed vehicle

high accuracy with best machine tools gears and industrial gears

Medium Hobbing, shaping, milling 8–9 8–9 Low speed vehicle gears

accuracy with best machine tools and industrial gears

Low accuracy Hobbing, shaping, milling 10–11 6–7 Low speed gears

with ordinary machine tools

Very low Casting, moulding 12 4–5 Low speed and light load

accuracy gears

width b = 10∼50 mm, linear velocity v = 10 m s −1 and reliability of 99% for a life of

7

5 × 10 cycles under repeated, unidirectional stable loads [16]. Although other factors,

such as gear dimensions, lubrication, temperature and so on are considered in design

handbooks and standards [9, 14], they are deemed to have minor effects on endurance

limits and therefore neglected for simplicity in this book.Contact endurance limits,

Hlim , and bending endurance limits, Flim , have a linear relationship with surface

hardness HBW for a soft tooth surface or HV for a hard tooth surface [16]. They are

also closely related to material quality grade. Table 8.6 lists the contact endurance

Table 8.6 Contact endurance limits, Hlim , and bending endurance limits, Flim , of selected gear

materials [16].

Contact Bending

endurance endurance

Hardness limits, limits,

Material Type HBW/HV Hlim ,MPa Flim ,MPa

Normalized cast steels Carbon steels 140–210 HBW 269–338 106–128

Cast iron materials Nodular cast iron 175–300 HBW 462–641 180–224

Grey cast iron 150–240 HBW 287–380 46–69

Through hardened Carbon steels 115–215 HV 484–554 191–215

wrought steels Alloy steels 200–360 HV 636–846 272–340

Through hardened cast Carbon steels 130–215 HV 408–479 146–165

steels Alloy steels 200–360 HV 553–757 234–292

Flame or induction Wrought and cast steels 500–615 HV 1153–1215 359–369

Nitriding steels/through Nitriding steels 650–900 HV 1250 420

hardening steels nitrided Through hardening steels 450–650 HV 998 363