Page 232 - Analysis and Design of Machine Elements

P. 232

Analysis and Design of Machine Elements

210

8.6.7 Design Cases

Example Problem 8.1

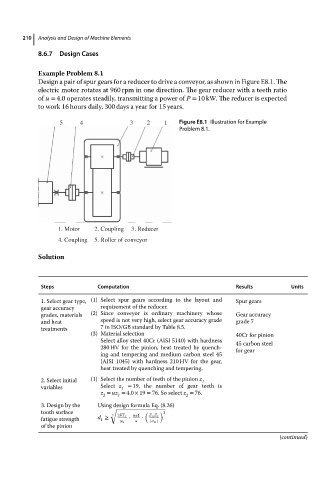

Design a pair of spur gears for a reducer to drive a conveyor, as shown in Figure E8.1. The

electric motor rotates at 960 rpm in one direction. The gear reducer with a teeth ratio

of u = 4.0 operates steadily, transmitting a power of P = 10 kW. The reducer is expected

to work 16 hours daily, 300 days a year for 15 years.

5 4 3 2 1 Figure E8.1 Illustration for Example

Problem 8.1.

1. Motor 2. Coupling 3. Reducer

4. Coupling 5. Roller of conveyor

Solution

Steps Computation Results Units

1. Select gear type, (1) Selectspurgears accordingtothe layout and Spur gears

gear accuracy requirement of the reducer.

grades, materials (2) Since conveyor is ordinary machinery whose Gear accuracy

and heat speed is not very high, select gear accuracy grade grade 7

treatments 7 in ISO/GB standard by Table 8.5.

(3) Material selection 40Cr for pinion

Select alloy steel 40Cr (AISI 5140) with hardness 45 carbon steel

280 HV for the pinion, heat treated by quench- for gear

ing and tempering and medium carbon steel 45

(AISI 1045) with hardness 210 HV for the gear,

heat treated by quenching and tempering.

2. Select initial (1) Select the number of teeth of the pinion z 1

variables Select z 1 = 19, thenumberofgearteeth is

z = uz = 4.0 × 19 = 76. So select z = 76.

2

1

2

3. Design by the Using design formula Eq. (8.26)

√

tooth surface 3 2KT 1 u±1 ( Z H Z E ) 2

fatigue strength d ≥ ⋅ ⋅

1

d u [ H ]

of the pinion

(continued)