Page 278 - Analysis and Design of Machine Elements

P. 278

Analysis and Design of Machine Elements

256

Output shaft Figure P9.2 Illustration for Calculation Question 2.

2 × 4

× ω 4

3

Input shaft

1

3 Awormgearwith41teeth andmoduleof m = 5 mm mates with a double-threaded

worm with a diameter of d = 50 mm. Assume the coefficient of friction is f = 0.1.

1

Determine (1) speed ratio, (2) diameter of wormgear, (3) centre distance, (4) lead

angle of the worm and whether the wormset is self-locking and (5) efficiency.

4 The input power for a wormgear reducer is P = 3 kWwithatotalefficiencyof = 0.8.

2

The heat dissipation area is 1 m and heat transfer coefficient is = 15 W m −2 ∘ C.

s

∘

Assume the ambient temperature is 20 C. It is required that the oil temperature

∘

does not exceed 80 C at heat balance. Please check whether the lubricant oil sump

temperature meets the requirements.

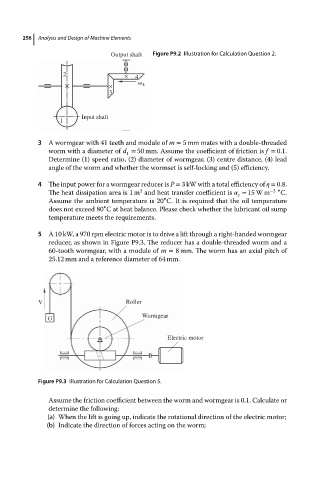

5 A 10 kW, a 970 rpm electric motor is to drive a lift through a right-handed wormgear

reducer, as shown in Figure P9.3. The reducer has a double-threaded worm and a

60-tooth wormgear, with a module of m = 8 mm. The worm hasanaxial pitchof

25.12 mm and a reference diameter of 64 mm.

V Roller

G Wormgear

Electric motor

Figure P9.3 Illustration for Calculation Question 5.

Assume the friction coefficient between the worm and wormgear is 0.1. Calculate or

determine the following:

(a) When the lift is going up, indicate the rotational direction of the electric motor;

(b) Indicate the direction of forces acting on the worm;