Page 275 - Analysis and Design of Machine Elements

P. 275

d1 d1 Wormgear Drives 253

b1 b1

(a) (b)

Figure 9.8 Worm structure.

(a) (b) (c) (d)

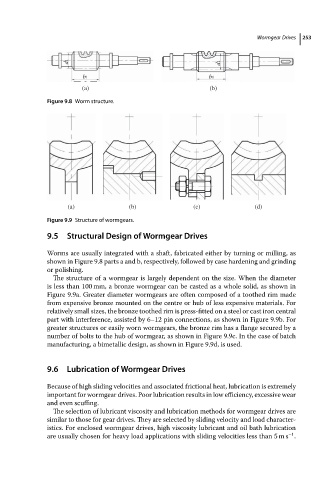

Figure 9.9 Structure of wormgears.

9.5 Structural Design of Wormgear Drives

Worms are usually integrated with a shaft, fabricated either by turning or milling, as

shown in Figure 9.8 parts a and b, respectively, followed by case hardening and grinding

or polishing.

The structure of a wormgear is largely dependent on the size. When the diameter

is less than 100 mm, a bronze wormgear can be casted as a whole solid, as shown in

Figure 9.9a. Greater diameter wormgears are often composed of a toothed rim made

from expensive bronze mounted on the centre or hub of less expensive materials. For

relatively small sizes, the bronze toothed rim is press-fitted on a steel or cast iron central

part with interference, assisted by 6–12 pin connections, as shown in Figure 9.9b. For

greater structures or easily worn wormgears, the bronze rim has a flange secured by a

number of bolts to the hub of wormgear, as shown in Figure 9.9c. In the case of batch

manufacturing, a bimetallic design, as shown in Figure 9.9d, is used.

9.6 Lubrication of Wormgear Drives

Because of high sliding velocities and associated frictional heat, lubrication is extremely

important for wormgear drives. Poor lubrication results in low efficiency, excessive wear

and even scuffing.

The selection of lubricant viscosity and lubrication methods for wormgear drives are

similar to those for gear drives. They are selected by sliding velocity and load character-

istics. For enclosed wormgear drives, high viscosity lubricant and oil bath lubrication

−1

are usually chosen for heavy load applications with sliding velocities less than 5 m s .