Page 86 - Analysis and Design of Machine Elements

P. 86

Analysis and Design of Machine Elements

64

3.3 Threaded Fastening Methods

3.3.1 Types of Threaded Fastening Methods

Threaded fastenings are the basic assembly method in the design and construction of

machines. Threaded fasteners join the matching external and internal threads together

by the following typical methods.

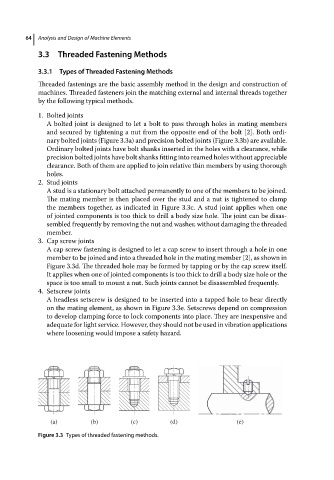

1. Bolted joints

A bolted joint is designed to let a bolt to pass through holes in mating members

and secured by tightening a nut from the opposite end of the bolt [2]. Both ordi-

nary bolted joints (Figure 3.3a) and precision bolted joints (Figure 3.3b) are available.

Ordinary bolted joints have bolt shanks inserted in the holes with a clearance, while

precision bolted joints have bolt shanks fitting into reamed holes without appreciable

clearance. Both of them are applied to join relative thin members by using thorough

holes.

2. Stud joints

A stud is a stationary bolt attached permanently to one of the members to be joined.

The mating member is then placed over the stud and a nut is tightened to clamp

the members together, as indicated in Figure 3.3c. A stud joint applies when one

of jointed components is too thick to drill a body size hole. The joint can be disas-

sembled frequently by removing the nut and washer, without damaging the threaded

member.

3. Cap screw joints

A cap screw fastening is designed to let a cap screw to insert through a hole in one

member to be joined and into a threaded hole in the mating member [2], as shown in

Figure 3.3d. The threaded hole may be formed by tapping or by the cap screw itself.

It applies when one of jointed components is too thick to drill a body size hole or the

spaceistoo smalltomountanut. Such joints cannotbedisassembledfrequently.

4. Setscrew joints

A headless setscrew is designed to be inserted into a tapped hole to bear directly

on the mating element, as shown in Figure 3.3e. Setscrews depend on compression

to develop clamping force to lock components into place. They are inexpensive and

adequate for light service. However, they should not be used in vibration applications

where loosening would impose a safety hazard.

(a) (b) (c) (d) (e)

Figure 3.3 Types of threaded fastening methods.