Page 211 - Analytical Electrochemistry 2d Ed - Jospeh Wang

P. 211

196 ELECTROCHEMICAL SENSORS

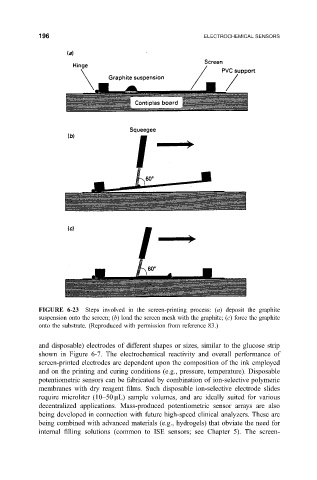

FIGURE 6-23 Steps involved in the screen-printing process: (a) deposit the graphite

suspension onto the screen; (b) load the screen mesh with the graphite; (c) force the graphite

onto the substrate. (Reproduced with permission from reference 83.)

and disposable) electrodes of different shapes or sizes, similar to the glucose strip

shown in Figure 6-7. The electrochemical reactivity and overall performance of

screen-printed electrodes are dependent upon the composition of the ink employed

and on the printing and curing conditions (e.g., pressure, temperature). Disposable

potentiometric sensors can be fabricated by combination of ion-selective polymeric

membranes with dry reagent ®lms. Such disposable ion-selective electrode slides

require microliter (10±50 mL) sample volumes, and are ideally suited for various

decentralized applications. Mass-produced potentiometric sensor arrays are also

being developed in connection with future high-speed clinical analyzers. These are

being combined with advanced materials (e.g., hydrogels) that obviate the need for

internal ®lling solutions (common to ISE sensors; see Chapter 5). The screen-