Page 209 - Analytical Electrochemistry 2d Ed - Jospeh Wang

P. 209

194 ELECTROCHEMICAL SENSORS

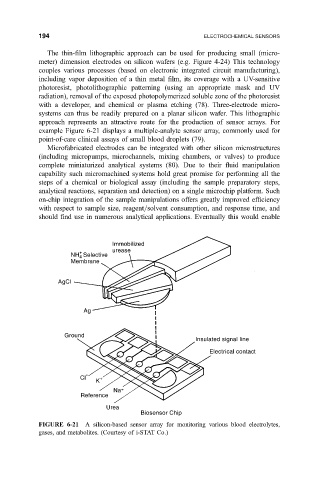

The thin-®lm lithographic approach can be used for producing small (micro-

meter) dimension electrodes on silicon wafers (e.g. Figure 4-24) This technology

couples various processes (based on electronic integrated circuit manufacturing),

including vapor deposition of a thin metal ®lm, its coverage with a UV-sensitive

photoresist, photolithographic patterning (using an appropriate mask and UV

radiation), removal of the exposed photopolymerized soluble zone of the photoresist

with a developer, and chemical or plasma etching (78). Three-electrode micro-

systems can thus be readily prepared on a planar silicon wafer. This lithographic

approach represents an attractive route for the production of sensor arrays. For

example Figure 6-21 displays a multiple-analyte sensor array, commonly used for

point-of-care clinical assays of small blood droplets (79).

Microfabricated electrodes can be integrated with other silicon microstructures

(including micropumps, microchannels, mixing chambers, or valves) to produce

complete miniaturized analytical systems (80). Due to their ¯uid manipulation

capability such micromachined systems hold great promise for performing all the

steps of a chemical or biological assay (including the sample preparatory steps,

analytical reactions, separation and detection) on a single microchip platform. Such

on-chip integration of the sample manipulations offers greatly improved ef®ciency

with respect to sample size, reagent=solvent consumption, and response time, and

should ®nd use in numerous analytical applications. Eventually this would enable

FIGURE 6-21 A silicon-based sensor array for monitoring various blood electrolytes,

gases, and metabolites. (Courtesy of i-STAT Co.)