Page 210 - Analytical Electrochemistry 2d Ed - Jospeh Wang

P. 210

6-3 SOLID-STATE DEVICES 195

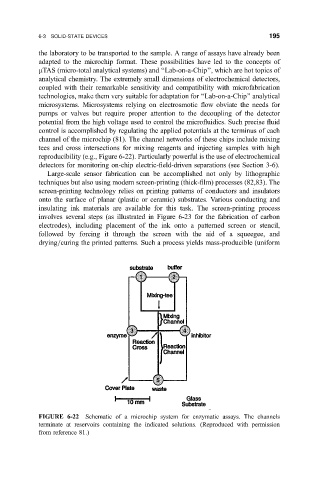

the laboratory to be transported to the sample. A range of assays have already been

adapted to the microchip format. These possibilities have led to the concepts of

mTAS (micro-total analytical systems) and ``Lab-on-a-Chip'', which are hot topics of

analytical chemistry. The extremely small dimensions of electrochemical detectors,

coupled with their remarkable sensitivity and compatibility with microfabrication

technologies, make them very suitable for adaptation for ``Lab-on-a-Chip'' analytical

microsystems. Microsystems relying on electrosmotic ¯ow obviate the needs for

pumps or valves but require proper attention to the decoupling of the detector

potential from the high voltage used to control the micro¯uidics. Such precise ¯uid

control is accomplished by regulating the applied potentials at the terminus of each

channel of the microchip (81). The channel networks of these chips include mixing

tees and cross intersections for mixing reagents and injecting samples with high

reproducibility (e.g., Figure 6-22). Particularly powerful is the use of electrochemical

detectors for monitoring on-chip electric-®eld-driven separations (see Section 3-6).

Large-scale sensor fabrication can be accomplished not only by lithographic

techniques but also using modern screen-printing (thick-®lm) processes (82,83). The

screen-printing technology relies on printing patterns of conductors and insulators

onto the surface of planar (plastic or ceramic) substrates. Various conducting and

insulating ink materials are available for this task. The screen-printing process

involves several steps (as illustrated in Figure 6-23 for the fabrication of carbon

electrodes), including placement of the ink onto a patterned screen or stencil,

followed by forcing it through the screen with the aid of a squeegee, and

drying=curing the printed patterns. Such a process yields mass-producible (uniform

FIGURE 6-22 Schematic of a microchip system for enzymatic assays. The channels

terminate at reservoirs containing the indicated solutions. (Reproduced with permission

from reference 81.)