Page 195 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 195

66131_Ludwig_CH10F 5/30/2001 4:35 PM Page 158

158 Applied Process Design for Chemical and Petrochemical Plants

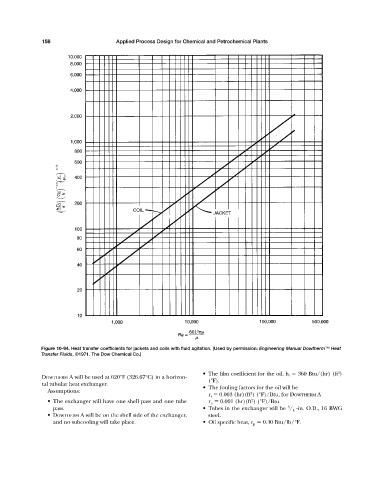

Figure 10-94. Heat transfer coefficients for jackets and coils with fluid agitation. (Used by permission: Engineering Manual Dowtherm™ Heat

Transfer Fluids, ©1971. The Dow Chemical Co.)

• The film coefficient for the oil, h i 360 Btu/(hr) (ft )

2

DOWTHERM A will be used at 620°F (326.67°C) in a horizon-

(°F).

tal tubular heat exchanger.

• The fouling factors for the oil will be

Assumptions:

2

r i 0.003 (hr)(ft ) (°F)/Btu, for DOWTHERM A

• The exchanger will have one shell pass and one tube r o 0.001 (hr)(ft ) (°F)/Btu

2

3

pass. • Tubes in the exchanger will be / 4 -in. O.D., 16 BWG

• DOWTHERM A will be on the shell side of the exchanger, steel.

and no subcooling will take place. • Oil specific heat, c p 0.40 Btu/lb/°F.