Page 200 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 200

66131_Ludwig_CH10F 5/30/2001 4:35 PM Page 163

Heat Transfer 163

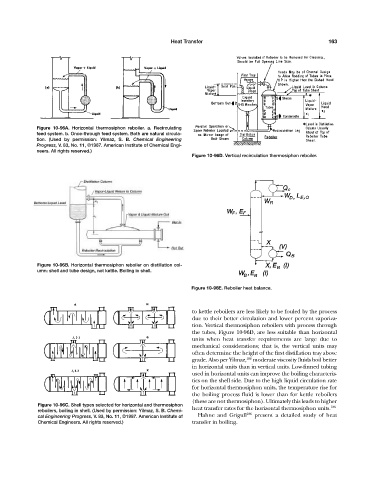

Figure 10-96A. Horizontal thermosiphon reboiler. a. Recirculating

feed system. b. Once-through feed system. Both are natural circula-

tion. (Used by permission: Yilmaz, S. B. Chemical Engineering

Progress, V. 83, No. 11, ©1987. American Institute of Chemical Engi-

neers. All rights reserved.)

Figure 10-96D. Vertical recirculation thermosiphon reboiler.

Figure 10-96B. Horizontal thermosiphon reboiler on distillation col-

umn: shell and tube design, not kettle. Boiling in shell.

Figure 10-96E. Reboiler heat balance.

to kettle reboilers are less likely to be fouled by the process

due to their better circulation and lower percent vaporiza-

tion. Vertical thermosiphon reboilers with process through

the tubes, Figure 10-96D, are less suitable than horizontal

units when heat transfer requirements are large due to

mechanical considerations; that is, the vertical units may

often determine the height of the first distillation tray above

grade. Also per Yilmaz, 186 moderate viscosity fluids boil better

in horizontal units than in vertical units. Low-finned tubing

used in horizontal units can improve the boiling characteris-

tics on the shell side. Due to the high liquid circulation rate

for horizontal thermosiphon units, the temperature rise for

the boiling process fluid is lower than for kettle reboilers

(these are not thermosiphon). Ultimately this leads to higher

Figure 10-96C. Shell types selected for horizontal and thermosiphon 186

reboilers, boiling in shell. (Used by permission: Yilmaz, S. B. Chemi- heat transfer rates for the horizontal thermosiphon units.

186

cal Engineering Progress, V. 83, No. 11, ©1987. American Institute of Hahne and Grigull present a detailed study of heat

Chemical Engineers. All rights reserved.) transfer in boiling.