Page 290 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 290

66131_Ludwig_CH10G 5/30/2001 4:40 PM Page 252

252 Applied Process Design for Chemical and Petrochemical Plants

E. Baffle Tray Column (or, Termed Shower Deck, No Holes, Caps,

or Other Contact Devices)

For counter flow, gas flowing up a column through a

falling shower film of liquid, Fair’s correlation 242 of collected

data is to be used as a guide:

U a 0.011 G 1.04 L 0.3 (10-284)

See Fair’s reference given previously for nomenclature.

For baffle trays, the coefficient equation given under

packed columns, the values of m 1.18 and n 0.44 with C 1

depending on the system. For example, for a

nitrogen/absorption oil system, C 1 0.00250. See the ref-

erence and Table 10-48 for more details.

Air-Cooled Heat Exchangers

Air-cooled heat exchangers are very seldom, if ever, finally

designed by the user company (or engineering design con-

tractor), because the best final designs are prepared by the

manufacturers specializing in this unique design and requir-

ing special data. This topic is presented here to aid the engi-

neer in understanding the equipment and applications, but

not to provide methods for preparing final fabrication

designs. 106, 206, 251, 252, 253, 254, 255, 256, 257, 258, 259, 260, 261, 262, 263, 264, 265 Stan-

dard 661, 3 rd Ed., American Petroleum Institute, “Air

Cooled Heat Exchangers for General Refinery Services” is a

good basic reference.

Air-cooled exchangers use atmospheric air on the outside

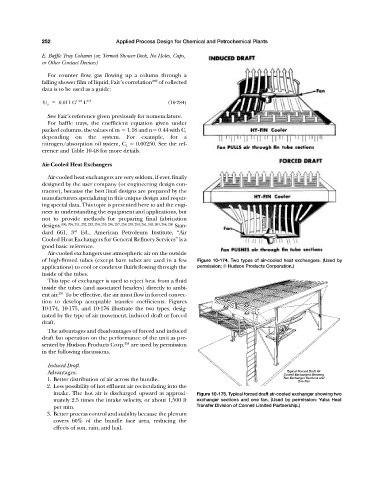

of high-finned tubes (except bare tubes are used in a few Figure 10-174. Two types of air-cooled heat exchangers. (Used by

applications) to cool or condense fluids flowing through the permission: © Hudson Products Corporation.)

inside of the tubes.

This type of exchanger is used to reject heat from a fluid

inside the tubes (and associated headers) directly to ambi-

ent air. 251 To be effective, the air must flow in forced convec-

tion to develop acceptable transfer coefficients. Figures

10-174, 10-175, and 10-176 illustrate the two types, desig-

nated by the type of air movement, induced draft or forced

draft.

The advantages and disadvantages of forced and induced

draft fan operation on the performance of the unit as pre-

sented by Hudson Products Corp. 251 are used by permission

in the following discussions.

Induced Draft.

Advantages:

1. Better distribution of air across the bundle.

2. Less possibility of hot effluent air recirculating into the

intake. The hot air is discharged upward at approxi- Figure 10-175. Typical forced draft air-cooled exchanger showing two

mately 2.5 times the intake velocity, or about 1,500 ft exchanger sections and one fan. (Used by permission: Yuba Heat

per min. Transfer Division of Connell Limited Partnership.)

3. Better process control and stability because the plenum

covers 60% of the bundle face area, reducing the

effects of sun, rain, and hail.