Page 291 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 291

66131_Ludwig_CH10G 5/30/2001 4:40 PM Page 253

Heat Transfer 253

3. Low natural draft capability on fan failure.

4. Complete exposure of the finned tubes to sun, rain,

and hail, which results in poor process control and

stability.

Hudson 251 states that the advantages of the induced draft

design outweigh the disadvantages.

Although most units are installed horizontally, inclined,

Figure 10-177, and vertical units are also in service. Figures

10-178 and 10-179 show typical assemblies for tube bundles

with fabricated or cast end headers and also with flanged

cover plates.

The tube bundle is an assembly of tubes rolled into

tubesheets and assembled into headers. See Figures 10-175,

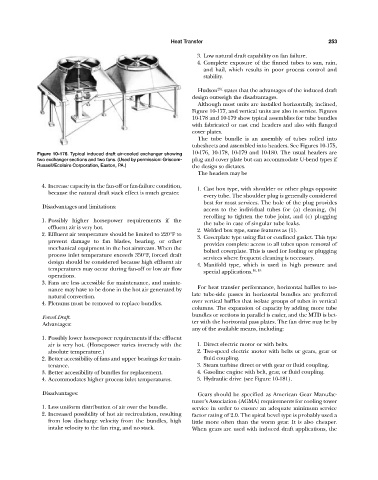

Figure 10-176. Typical induced draft air-cooled exchanger showing 10-176, 10-178, 10-179 and 10-180. The usual headers are

two exchanger sections and two fans. (Used by permission: Griscom- plug and cover plate but can accommodate U-bend types if

Russell/Ecolaire Corporation, Easton, PA.) the design so dictates.

The headers may be

4. Increase capacity in the fan-off or fan-failure condition,

1. Cast box type, with shoulder or other plugs opposite

because the natural draft stack effect is much greater.

every tube. The shoulder plug is generally considered

best for most services. The hole of the plug provides

Disadvantages and limitations:

access to the individual tubes for (a) cleaning, (b)

rerolling to tighten the tube joint, and (c) plugging

1. Possibly higher horsepower requirements if the

the tube in case of singular tube leaks.

effluent air is very hot.

2. Welded box type, same features as (1).

2. Effluent air temperature should be limited to 220°F to

3. Coverplate type using flat or confined gasket. This type

prevent damage to fan blades, bearing, or other

provides complete access to all tubes upon removal of

mechanical equipment in the hot airstream. When the

bolted coverplate. This is used for fouling or plugging

process inlet temperature exceeds 350°F, forced draft

services where frequent cleaning is necessary.

design should be considered because high effluent air

4. Manifold type, which is used in high pressure and

temperatures may occur during fan-off or low air flow 16, 18

special applications.

operations.

3. Fans are less accessible for maintenance, and mainte-

For heat transfer performance, horizontal baffles to iso-

nance may have to be done in the hot air generated by

late tube-side passes in horizontal bundles are preferred

natural convection.

over vertical baffles that isolate groups of tubes in vertical

4. Plenums must be removed to replace bundles.

columns. The expansion of capacity by adding more tube

bundles or sections in parallel is easier, and the MTD is bet-

Forced Draft.

ter with the horizontal pass plates. The fan drive may be by

Advantages:

any of the available means, including:

1. Possibly lower horsepower requirements if the effluent

air is very hot. (Horsepower varies inversely with the 1. Direct electric motor or with belts.

absolute temperature.) 2. Two-speed electric motor with belts or gears, gear or

2. Better accessibility of fans and upper bearings for main- fluid coupling.

tenance. 3. Steam turbine direct or with gear or fluid coupling.

3. Better accessibility of bundles for replacement. 4. Gasoline engine with belt, gear, or fluid coupling.

4. Accommodates higher process inlet temperatures. 5. Hydraulic drive (see Figure 10-181).

Disadvantages: Gears should be specified as American Gear Manufac-

turer’s Association (AGMA) requirements for cooling tower

1. Less uniform distribution of air over the bundle. service in order to ensure an adequate minimum service

2. Increased possibility of hot air recirculation, resulting factor rating of 2.0. The spiral bevel type is probably used a

from low discharge velocity from the bundles, high little more often than the worm gear. It is also cheaper.

intake velocity to the fan ring, and no stack. When gears are used with induced draft applications, the