Page 343 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 343

66131_Ludwig_CH11A 5/30/2001 4:49 PM Page 301

Refrigeration Systems 301

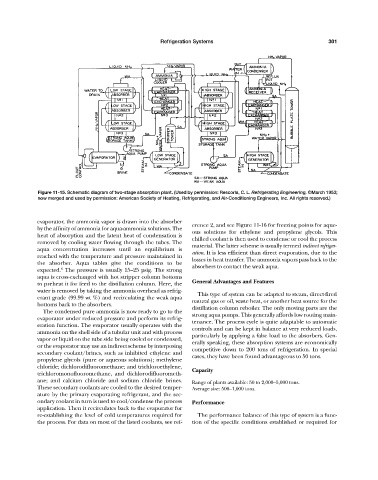

Figure 11-15. Schematic diagram of two-stage absorption plant. (Used by permission: Rescorla, C. L. Refrigerating Engineering, ©March 1953;

now merged and used by permission: American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. All rights reserved.)

evaporator, the ammonia vapor is drawn into the absorber

erence 2, and see Figure 11-16 for freezing points for aque-

by the affinity of ammonia for aqua-ammonia solutions. The

ous solutions for ethylene and propylene glycols. This

heat of absorption and the latent heat of condensation is

chilled coolant is then used to condense or cool the process

removed by cooling water flowing through the tubes. The

material. The latter scheme is usually termed indirect refriger-

aqua concentration increases until an equilibrium is

ation. It is less efficient than direct evaporation, due to the

reached with the temperature and pressure maintained in

losses in heat transfer. The ammonia vapors pass back to the

the absorber. Aqua tables give the conditions to be absorbers to contact the weak aqua.

6

expected. The pressure is usually 15—25 psig. The strong

aqua is cross-exchanged with hot stripper column bottoms

General Advantages and Features

to preheat it for feed to the distillation column. Here, the

water is removed by taking the ammonia overhead as refrig-

This type of system can be adapted to steam, direct-fired

erant grade (99.99 wt %) and recirculating the weak aqua

natural gas or oil, waste heat, or another heat source for the

bottoms back to the absorbers.

distillation column reboiler. The only moving parts are the

The condensed pure ammonia is now ready to go to the

strong aqua pumps. This generally affords low routing main-

evaporator under reduced pressure and perform its refrig-

tenance. The process cycle is quite adaptable to automatic

eration function. The evaporator usually operates with the

controls and can be kept in balance at very reduced loads,

ammonia on the shell side of a tubular unit and with process

particularly by applying a false load to the absorbers. Gen-

vapor or liquid on the tube side being cooled or condensed,

erally speaking, these absorption systems are economically

or the evaporator may use an indirect scheme by interposing

competitive down to 200 tons of refrigeration. In special

secondary coolant/brines, such as inhibited ethylene and

cases, they have been found advantageous to 50 tons.

propylene glycols (pure or aqueous solutions); methylene

chloride; dichlorodifluoromethane; and trichloroethylene,

Capacity

trichloromonofluoromethane, and dichlorodifluorometh-

ane; and calcium chloride and sodium chloride brines. Range of plants available: 50 to 2,000—5,000 tons.

These secondary coolants are cooled to the desired temper- Average size: 500—1,000 tons.

ature by the primary evaporating refrigerant, and the sec-

ondary coolant in turn is used to cool/condense the process Performance

application. Then it recirculates back to the evaporator for

re-establishing the level of cold temperatures required for The performance balance of this type of system is a func-

the process. For data on most of the listed coolants, see ref- tion of the specific conditions established or required for