Page 412 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 412

66131_Ludwig_CH12A 6/1/01 11:00 AM Page 369

Compression Equipment (Including Fans) 369

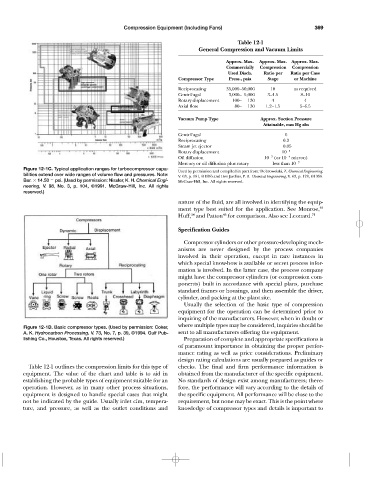

Table 12-1

General Compression and Vacuum Limits

Approx. Max. Approx. Max. Approx. Max.

Commercially Compression Compression

Used Disch. Ratio per Ratio per Case

Compressor Type Press., psia Stage or Machine

Reciprocating 35,000—50,000 10 as required

Centrifugal 03,000—05,000 3—4.5 8—10

Rotary displacement 0,0100—0,0130 4 4

Axial flow 0,0080—0,0130 1.2—1.5 5—6.5

Vacuum Pump Type Approx. Suction Pressure

Attainable, mm Hg abs

Centrifugal 6

Reciprocating 0.3

Steam jet ejector 00.05

Rotary displacement 10 5

Oil diffusion 10 7 (or 10 4 micron)

Mercury or oil diffusion plus rotary less than 10 7

Figure 12-1C. Typical application ranges for turbocompressor capa-

Used by permission and compiled in part from: Dobrowolski, Z. Chemical Engineering,

bilities extend over wide ranges of volume flow and pressures. Note: V. 63, p. 181, ©1956 and Des Jardins, P. R. Chemical Engineering, V. 63, p. 178, ©1956.

Bar. 14.50 psi. (Used by permission: Nissler, K. H. Chemical Engi- McGraw-Hill, Inc. All rights reserved.

neering, V. 98, No. 3, p. 104, ©1991. McGraw-Hill, Inc. All rights

reserved.)

nature of the fluid, are all involved in identifying the equip-

ment type best suited for the application. See Monroe, 40

34

43

Huff, and Patton for comparison. Also see Leonard. 71

Specification Guides

Compressor cylinders or other pressure-developing mech-

anisms are never designed by the process companies

involved in their operation, except in rare instances in

which special know-how is available or secret process infor-

mation is involved. In the latter case, the process company

might have the compressor cylinders (or compression com-

ponents) built in accordance with special plans, purchase

standard frames or housings, and then assemble the driver,

cylinder, and packing at the plant site.

Usually the selection of the basic type of compression

equipment for the operation can be determined prior to

inquiring of the manufacturers. However, when in doubt or

where multiple types may be considered, inquiries should be

Figure 12-1D. Basic compressor types. (Used by permission: Coker,

A. K. Hydrocarbon Processing, V. 73, No. 7, p. 39, ©1994. Gulf Pub- sent to all manufacturers offering the equipment.

lishing Co., Houston, Texas. All rights reserved.) Preparation of complete and appropriate specifications is

of paramount importance in obtaining the proper perfor-

mance rating as well as price considerations. Preliminary

design rating calculations are usually prepared as guides or

Table 12-1 outlines the compression limits for this type of checks. The final and firm performance information is

equipment. The value of the chart and table is to aid in obtained from the manufacturer of the specific equipment.

establishing the probable types of equipment suitable for an No standards of design exist among manufacturers; there-

operation. However, as in many other process situations, fore, the performance will vary according to the details of

equipment is designed to handle special cases that might the specific equipment. All performance will be close to the

not be indicated by the guide. Usually inlet cfm, tempera- requirement, but none may be exact. This is the point where

ture, and pressure, as well as the outlet conditions and knowledge of compressor types and details is important to