Page 104 - Applied Photovoltaics

P. 104

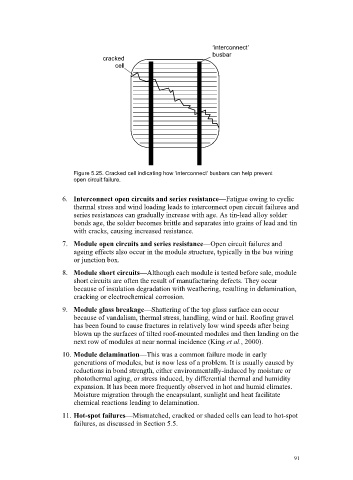

‘interconnect’

busbar

cracked

cell

Figure 5.25. Cracked cell indicating how ‘interconnect’ busbars can help prevent

open circuit failure.

6. Interconnect open circuits and series resistance—Fatigue owing to cyclic

thermal stress and wind loading leads to interconnect open circuit failures and

series resistances can gradually increase with age. As tin-lead alloy solder

bonds age, the solder becomes brittle and separates into grains of lead and tin

with cracks, causing increased resistance.

7. Module open circuits and series resistance—Open circuit failures and

ageing effects also occur in the module structure, typically in the bus wiring

or junction box.

8. Module short circuits—Although each module is tested before sale, module

short circuits are often the result of manufacturing defects. They occur

because of insulation degradation with weathering, resulting in delamination,

cracking or electrochemical corrosion.

9. Module glass breakage—Shattering of the top glass surface can occur

because of vandalism, thermal stress, handling, wind or hail. Roofing gravel

has been found to cause fractures in relatively low wind speeds after being

blown up the surfaces of tilted roof-mounted modules and then landing on the

next row of modules at near normal incidence (King et al., 2000).

10. Module delamination—This was a common failure mode in early

generations of modules, but is now less of a problem. It is usually caused by

reductions in bond strength, either environmentally-induced by moisture or

photothermal aging, or stress induced, by differential thermal and humidity

expansion. It has been more frequently observed in hot and humid climates.

Moisture migration through the encapsulant, sunlight and heat facilitate

chemical reactions leading to delamination.

11. Hot-spot failures—Mismatched, cracked or shaded cells can lead to hot-spot

failures, as discussed in Section 5.5.

91