Page 186 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 186

Pumping of Liquids 161

Table 3-1 The centrifugal pump (Table 3-2) develops its pressure

General Types or Classification of Pumps by centrifugal force on the liquid passing through the

All types will not be treated in detail, but consideration of pump and is generally applicable to high capacity, low to

their particular features is important in many situations. medium head installations. In order to satisfy pump dis-

charge head (or pressure) requirements the unit may be

Centrifugal Rotary Reciprocating a multistage (multiple impellers) instead of a single stage

1. Centrifugal 1. Cam 1. Piston [28]. The conditions of pumping water vs. pumping hot

2. Propeller 2. Screw 2. Plunger light hydrocarbons require considerably different evalua-

3. Mixed Flow 3. Gear 3. Diaphragm tion in pump design features for satisfactory operation,

4. Peripheral 4. Vane safety and maintenance.

5. Turbine 5. Lobe

6. Radial Flow 6. Piston The inline centrifugal process pump, Figure 3-3, is rel-

7. Axial Flow 7. Flexible Rotor atively new to general applications; however, it is finding

many applications where space and installation costs are

important. Each application must be carefully evaluated,

as there are three basic types of pump construction to

consider. Generally, for many applications the dimensions

have been standardized through the American Voluntary

Standard, ANSI, or MI-610. The performance curves are

typical of single stage centrifugal pumps.

The turbine is a special type of centrifugal pump (Fig-

ure 3-14) and has limited special purpose applications.

Pump Design Standardization

Certain pump designs have been standardized to aid

manufacturer’s problems, and to allow the owners to take

advantage of standardization of parts and dimensions,

and consequently maintain a more useful inventory. The

standards are sponsored through the American National

Standards Institute; however, many manufacturers also

produce to the American Petroleum Institute and their

own proprietary standards. These are special pumps that

do not conform to all the standards, but are designed to

accomplish specific pumping services.

The primary pump types for the chemical industry for

horizontal and vertical inline applications have been stan-

I I I II I l l

lb 11 10 13 101 11 55 9 15 ldr dardized in ANSI E123, ANSI Std ## B73.1M for horizon-

tal end suction centrifugal pumps, and ANSI B73.2M for

vertical inline centrifugal pumps. The standards are in a

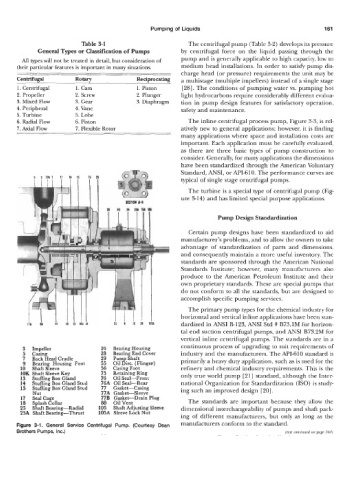

3 Impeller 26 Bearing Housing continuous process of upgrading to suit requirements of

5 Casing 28 Bearing End Cover industry and the manufacturers. The MI-610 standard is

7 Back Head Cradle 29 PumpShaft primarily a heavy duty application, such as is used for the

9 Bearing Housing Foot 55 Oil Disc. (Flinger)

10 Shaft Sleeve 56 CasingFoot refinery and chemical industry requirements. This is the

1OK Shaft Sleeve Key 75 Retaining Ring only true world pump [21] standard, although the Inter-

13 Stuffing Box Gland 76 Oil Seal-Front

14 Stuffing Box Gland Stud 76A Oil Seal-Rear national Organization for Standardization (ISO) is study-

15 Stuffing Box Gland Stud 77 Gasket-Casing ing such an improved design [20].

Nut 77A Gasketqleeve

17 SealCage 77B Gasket-Drain Plug

18 Splash Collar 80 OilVent The standards are important because they allow the

25 Shaft Bearing-Radial 105 Shaft Adjusting Sleeve dimensional interchangeability of pumps and shaft pack-

25A Shaft Bearing-Thrust 105A Sleeve Lock Nut

ing of different manufacturers, but only as long as the

Figure 3-1. General Service Centrifugal Pump. (Courtesy Dean manufacturers conform to the standard.

Brothers Pumps, Inc.) (text continued on page 164)