Page 214 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 214

186 Applied Process Design for Chemical and Petrochemical Plants

es are a function of the characteristics of the fluid flowing

in the piping systems and the velocities of flow. Entrance

and exit losses relate to the pipe and not the suction or

discharge connections at the pump. Usually they are very

small, but cannot be ignored without checking. Velocity b-

heads at the pump connections are considered internal e-

losses. These are handled by the manufacturer’s design of Pump

the pump and are not considered with the external losses

in establishing the pump heads. h, =S-h,,+P

J

(a 1

h, = -S- h,,+ P

Example 3-2: Illustrating Static, Pressure, and Friction (b)

Effects Note: When P is expressed in absolute pressure units,

hs will be in absolute units. If P is less than atmospheric

Refer to Figure 3-40F for basis of the example. pressure: P is (-) if expressed as a gauge reading and

To aid in speed of computation, the friction figures will be a negative feet of liquid. P is (+) if expressed in

are taken from the Cameron Hydraulic Tables in Chap- absolute units. The friction loss hSL includes any

entrance or exit losses and other such fittings in the

ter 2 and use water, which is suited to these tables, as an system.

example fluid.

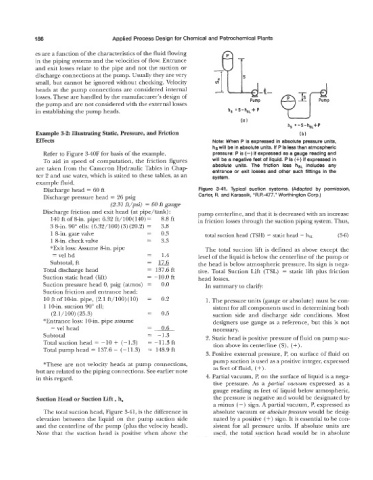

Discharge head = 60 ft Figure 3-41. Typical suction systems. (Adapted by permission,

Discharge pressure head = 26 psig Carter, R. and Karassik, “R.P.-477.” Worthington Corp.)

(2.31 ft/psi) = 60 ft gauge

Discharge friction and exit head (at pipe/tank): pump centerline, and that it is decreased with an increase

140 ft of 8-in. pipe: 6.32 ft/100(140) = 8.8 ft in friction losses through the suction piping system. Thus,

3 8-in. 90” ells: (6.32/100) (3) (20.2) = 3.8

1 8-in. gate valve = 0.3 total suction head (TSH) = static head - hSL (3-6)

1 8-in. check valve = 3.3

*Exit loss: Assume 8-in. pipe The total suction lift is defined as above except the

= vel hd = 1.4 level of the liquid is below the centerline of the pump or

Subtotal, ft =17.6 the head is below atmospheric pressure. Its sign is nega-

Total discharge head = 13’7.6 ft tive. Total Suction Lift (TSL) = static lift plus friction

Suction static head (lift) = -10.0 ft head losses.

Suction pressure head 0, psig (atmos) = 0.0 In summary to clarify:

Suction friction and entrance head:

10 ft of 10-in. pipe, (2.1 ft/lOO) (10) = 0.2 1. The pressure units (gauge or absolute) must be con-

1 10-in. suction 90” ell; sistent for all components used in determining both

(2.1/100) (25.3) = 0.5 suction side and discharge side conditions. Most

*Entrance loss: 10-in. pipe assume designers use gauge as a reference, but this is not

= vel head = 0.6 necessary.

Subtotal = -1.3 2. Static head is positive pressure of fluid on pump suc-

Total suction head = -10 + (-1.3) = -11.3 ft tion above its centerline (S), (+).

Total pump head = 13’7.6 - (-11.3) = 148.9 ft

3. Positive external pressure, P, on surface of fluid on

pump suction is used as a positive integer, expressed

*These are not velocity heads at pump connections,

but are related to the piping connections. See earlier note as feet of fluid, (+) .

in this regard. 4. Partial vacuum, P, on the surface of liquid is a nega-

tive pressure. As a partial vacuum expressed as a

gauge reading as feet of liquid below atmospheric,

Suction Head or Suction Lift, h, the pressure is negative and would be designated by

a minus (-) sign. A partial vacuum, P, expressed as

The total suction head, Figure 3-41, is the difference in absolute vacuum or absolute pressure would be desig-

elevation between the liquid on the pump suction side nated by a positive (+) sign. It is essential to be con-

and the centerline of the pump (plus the velocity head). sistent for all pressure units. If absolute units are

Note that the suction head is positive when above the used, the total suction head would be in absolute