Page 217 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 217

Pumping of Liquids 189

Cavitation of a centrifugal pump, or any pump, devel- worst possible operating conditions (see pump

ops when there is insufficient NPSH for the liquid to flow curves Figures 3-36A, B, C) with pump curve values

into the inlet of the pump, allowing flashing or bubble for NPSH expressed as feet of liquid handled. These are

formation in the suction system and entrance to the the pump’s required minimum NPSHR. The pump’s

pump. Each pump design or “famiky” of dimensional fea- piping and physical external system provides the

tures related to the inlet and impeller eye area and available NPSHk

entrance pattern requires a specific minimum value of

NPSM to operate satisfactorily without flashing, cavitating, NPSHA must be > NPSHR (3-8)

and loss of suction flow.

Under cavitating conditions a pump will perform 2. Internal clearance wear inside pump.

below its head-perfoicmance curve at any particular flow 3. Plugs in suction piping system (screens, nozzles,

rate. Although the pump may operate under cavitation etc.).

conditions, it will often be noisy lbecause of collapsing 4. Entrained gas (non-condensable) .

vapor bubbles and severe pitting, and erosion of the 5. Deviations or fluctuations in suction side pressures,

impeller often results. This damage can become so severe temperatures (increases), low liquid Bevel.

as to completely destroy the impeller and create excessive 6. Piping layout on suction, particularly tee-intersec-

clearances in the casing. To avoid these problems, the fol- tions, globe valves, baffles, long Lines with numerous

lowing are a few situations to watch: elbows.

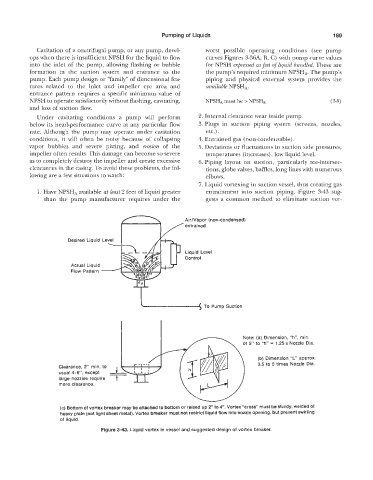

’7. Liquid vortexing in suction vessel, thus creating gas

1. Have NPSHA available at least 2 feet of liquid greater entrainment into suction piping. Figure 3-43 sug-

than the pump manufacturer requires under the gests a common method to eliminate suction vor-

AirNapor (non-condensed)

entrained

Desired Liquid Le

Liquid Level

Control

Actual Liquid

Flow Pattern

--+ To Pump Suction

Note: (a) Dimension, “h”, min.

of 5“ to “h“ = 1.25 x Nozzle Dia.

(b) Dimension “L” approx.

3.5 to 5 times Nozzle Dia.

Clearance, 2” min. to

usual 4-6”, except

large nozzles require

more clearance.

(@) Bottom Of vortex bt‘eakeir may be attached to bottom or raised up 2 to 4“. Vortex “cross” must be sturdy, Welded Of

heavy plate (not light sheet imetal). Vortex bhaker must not restrict liquid flow into nozzle opening, but prevent swirling

of liquid.

Figure 3-43. Liquid vortex in vessel and suggested design of vortex breaker.