Page 212 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 212

184 Applied Process Design for Chemical and Petrochemical Plants

- _-------

ua

0

-

Atmospheric -0 0

P

Pressure

V .-

I

4-

4- c Suction Discharge IL c

a

GO

Liquid Head Head a2 Suction: hs=S-hsL

I

W Y h,,=Pipe, Fittings and

I c other Friction Losses

0

u

YI

;3 Discharge: hd 'D*hdL

hdL:Pipe,Fittings and

other Friction Losses

fTRs

Liquid

*Suction: h, = -SL - hFL.

hSL = Pipe, Fitting, Valves,

ExchanQer and

Si other Friction

Losses

Entrance Loss -hs = SL+ hSL

**Discharge: hd = D + hdL

hdL = Pipe, Fittings and

other Friction

Losses

*Suction: Worst Case = SIL (Substitute in

above)

**Discharge: (Worst Case) use (D + D3

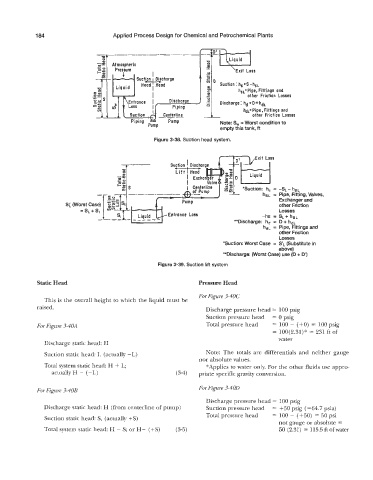

Figure 3-39. Suction lift system

Static Head Pressure Head

For Figure 3-40C

This is the overall height to which the liquid must be

raised. Discharge pressure head = 100 psig

Suction pressure head = 0 psig

For Figure 3-40A Total pressure head = 100 - (+O) = 100 psig

= 100(2.31)* = 231 ft of

water

Discharge static head: H

Suction static head: L (actually -L) Note: The totals are differentials and neither gauge

nor absolute values.

Total system static head: H + L; "Applies to water only. For the other fluids use appro-

actually H - (-L) (3-4) priate specific gravity conversion.

For Figure 3-400

For Figure 3-4OB

Discharge pressure head = 100 psig

Discharge static head: H (from centerline of pump) Suction pressure head = t50 psig (=64.'7 psia)

Total pressure head = 100 - (+50) = 50 psi

Suction static head: S, (actually +S)

not gauge or absolute =

Total system static head: H - S; or H- (+S) (3-5) 50 (2.31) = 115.5 ft ofwater