Page 134 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 134

Distillation 1 23

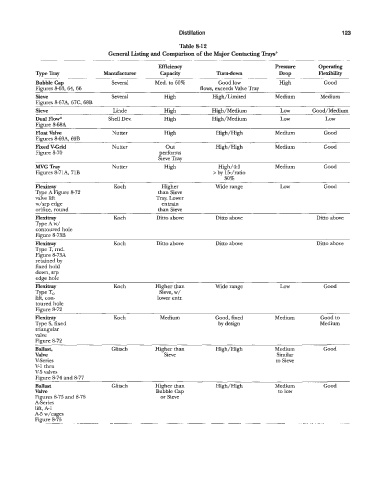

Table 8-12

General Listing and Comparison of the Major Contacting Trays+

Efficiency Pressure Operating

Tray Manufacturer Capacity Turn4own Drop Flexibility

. .. . ~ ~ . .~

Bubble Cap Several Med. to 60% Good low High Good

Figures 8-63, 64, 66 flows, exceeds Valve Tray

Sieve Several High High/Limi ted Medium Medium

Figures 867A, 67C, 68B

Sieve Linde High High/Medium Low Good/Medium

Dual Flow* Shell Dev. High High/Medium Low Low

Figure 868A

Float Valve Nutter High High/High Medium Good

Figures 8-69A, 69B

Fixed V-Grid Nutter out High/High Medium Good

Figure 8-70 performs

Sieve Tray

MVG Tray Nutter High High/4l Medium Good

Figures 87 I.A, 71B >by 15-/ratio

30 %

Flexitray Koch Higher Wide range Low Good

Type A Figure 8-72 than Sieve

valve lift Tray. Lower

w/srp edge entrain

orifice, round than Sieve

Flexitray Koch Ditto above Ditto above Ditto above

Type A w/

contoured hole

Figure 8-73B

Flexitray Koch Ditto above Ditto above Ditto above

Type T, rnd.

Figure 873A

retained by

fixed hold

down, srp

edge hole

Flexitray Koch Higher than Wide range Low Good

Type To Sieve, w/

lift, con- lower entr.

toured hole

Figure 8-72

Flexitray Koch Medium Good, fixed Medium Good to

Type S, fixed by design Medium

triangular

valve

Figure 8-72

Ballast, Glitsch Higher than High/High Medium Good

Valve Sieve Similar

V-Series to Sieve

V1 thru

V-5 valves

Figure 8-74 and 8-77

Ballast Glitsch Higher than High/High Medium Good

Valve Bubble Cap to low

Figures 8-73 and 8-76 or Sieve

A-Series

lift, A-l

A-5 w/cages

Figure 87.5

.

. .. .. . . -. . . . ... .... .-