Page 136 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 136

Distillation 125

'.--

2:

ezkStraight Downcomer Adjustable Outlet Weir

I

I

4-5"

t

\

ht

Hd

__

/--Tapered Downcomer

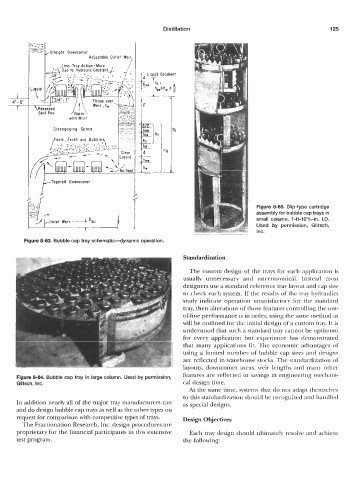

Figure 8-65. Slip-type cartridge

assembly for bubble cap trays in

small column, 1 -ft-1 O'YA-in. I.D.

Used by permission, Glitsch,

Inc.

Figure 8-63. Bubble cap tray schematic4ynamic operation.

Standardization

The custom design of the trays for each application is

usually unnecessary and uneconomical. Instead most

designers use a standard reference tray layout and cap size

to check each system. If the results of the tray hydraulics

study indicate operation unsatisfactory for the standard

tray, then alterations of those features controlling the out-

of-line performance is in order, using the same method as

will be outlined for the initial design of a custom tray. It is

understood that such a standard tray cannot be optimum

for every application but experience has demonstrated

that many applications fit. The economic advantages of

using a limited number of bubble cap sizes and designs

are reflected in warehouse stocks. The standardization of

layouts, downcomer areas, weir lengths and many other

features are reflected in savings in engineering mechani-

Figure 8-64. Bubble cap tray in large column. Used by permission,

Glitsch, Inc. cal design time.

At the same time, systems that do not adapt themselves

to this standardization should be recognized and handled

In addition nearly all of the major tray manufacturers can as special designs.

and do design bubble cap trays as well as the other types on

request for comparison with competitive types of trays. Design Objectives

The Fractionation Research, Inc. design procedures are

proprietary for the financial participants in this extensive Each tray design should ultimately resolve and achieve

test program. the following: