Page 283 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 283

272 Applied Process Design for Chemical and Petrochemical Plants

dency for rings to channel liquid to the tower wall. Saddle-

type packing does not require the use of the cone.

In packing a tower dry, high hydrostatic heads are thus

avoided on joint connections; however, extra care must be

taken to avoid ceramic breakage. The packing will proba-

bly settle after installation, but it should not be pressed or

tamped in place. This will cause extra breakage. The pack-

ing should not be allowed to fall more than two feet to the

bed surface. It should be dumped at random to avoid

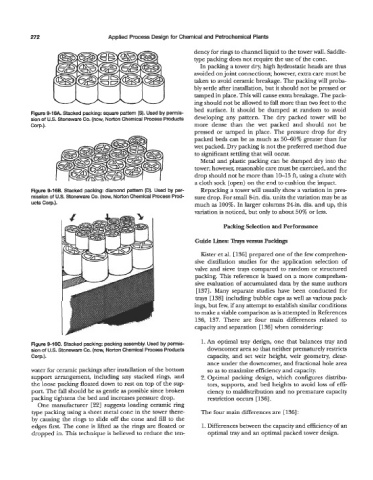

Figure 9-16A. Stacked packing: square pattern (S). Used by permis-

sion of U.S. Stoneware Co. (now, Norton Chemical Process Products developing any pattern. The dry packed tower will be

Corp.). more dense than the wet packed and should not be

pressed or tamped in place. The pressure drop for dry

packed beds can be as much as 50-60% greater than for

wet packed. Dry packing is not the preferred method due

to significant settling that will occur.

Metal and plastic packing can be dumped dry into the

tower; however, reasonable care must be exercised, and the

drop should not be more than 10-15 ft, using a chute with

a cloth sock (open) on the end to cushion the impact.

Figure 9-166. Stacked packing: diamond pattern (D). Used by per- Repacking a tower will usually show a variation in pres-

mission of U.S. Stoneware Co. (now, Norton Chemical Process Prod- sure drop. For small 8-in. dia. units the variation may be as

ucts Corp.). much as 100%. In larger columns 24in. dia. and up, this

variation is noticed, but only to about 50% or less.

Packing Selection and Performance

Guide Lines: Trays versus Packings

Kister et al. [136] prepared one of the few comprehen-

sive distillation studies for the application selection of

valve and sieve trays compared to random or structured

packing. This reference is based on a more comprehen-

sive evaluation of accumulated data by the same authors

[137]. Many separate studies have been conducted for

trays [138] including bubble caps as well as various pack-

ings, but few, if any attempt to establish similar conditions

to make a viable comparison as is attempted in References

136, 137. There are four main differences related to

capacity and separation [ 1361 when considering:

1. An optimal tray design, one that balances tray and

Figure 9-16C. Stacked packing: packing assembly. Used by permis-

sion of U.S. Stoneware Co. (now, Norton Chemical Process Products downcomer area so that neither prematurely restricts

Corp.). capacity, and set weir height, weir geometry, clear-

ance under the downcomer, and fractional hole area

water for ceramic packings after installation of the bottom so as to maximize efficiency and capacity.

support arrangement, including any stacked rings, and 2. Optimal packing design, which configures distribu-

the loose packing floated down to rest on top of the sup- tors, supports, and bed heights to avoid loss of effi-

port. The fall should be as gentle as possible since broken ciency to maldistribution and no premature capacity

packing tightens the bed and increases pressure drop. restriction occurs [ 1361.

One manufacturer [22] suggests loading ceramic ring

type packing using a sheet metal cone in the tower there- The four main differences are [ 1361 :

by causing the rings to slide off the cone and fill to the

edges first. The cone is lifted as the rings are floated or 1. Differences between the capacity and efficiency of an

dropped in. This technique is believed to reduce the ten- optimal tray and an optimal packed tower design.