Page 326 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 326

Mixing of Liquids 297

the system, in general being a function of viscosity,

impeller diameter and liquid depth in the tank. In gener-

al, dual impellers may be indicated for fluids of 45 cen-

tipoise and greater and where the fluid travels more than

four feet before being deflected.

The circulating capacity of %blade square pitch pro-

pellers is theoretically of the magnitude given in Figure 5-

9. The speed ranges indicated may be grouped as [2] :

high speed, 1750 rpm: for low viscosity fluids,

such as water

medium speed, 1150 rpm: for medium viscosity fluids,

such as light syrups and

varnishes

low speed, 420 rpm: for high viscosity fluids

such as oils, paints, or for

tender crystals or fibers: or

if foaming is a problem.

The mixing efficiency is generally higher (40%-60%)

for the slow 400 rpm speed and lower (25%-45%) for the

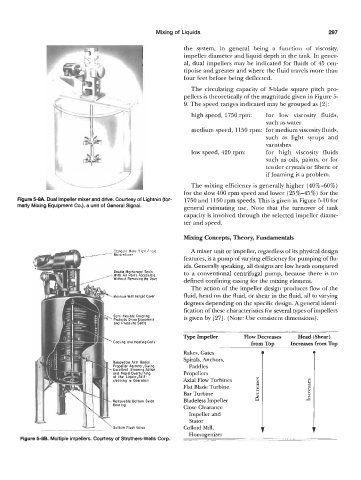

Figure 5-8A. Dual impeller mixer and drive. Courtesy of Lightnin (for- 1750 and 1150 rpm speeds. This is given in Figure 5-10 for

merly Mixing Equipment Co.), a unit of General Signal.

general estimating use. Note that the turnover of tank

capacity is involved through the selected impeller diame-

ter and speed.

Mixing Concepts, Theory, Fundamentals

A mixer unit or impeller, regardless of its physical design

features, is a pump of varying efficiency for pumping of flu-

ids. Generally speaking, all designs are low heads compared

to a conventional centrifugal pump, because there is no

defined confining casing for the mixing element.

The action of the impeller design produces flow of the

fluid, head on the fluid, or shear in the fluid, all to varying

degrees depending on the specific design. Ageneral identi-

fication of these characteristics for several types of impellers

is given by [27]. (Note: Use consistent dimensions).

Rakes, Gates 0

Spirals, Anchors,

Paddles

Propellers

Axial Flow Turbines m m

5

Flat Blade Turbine E 3

z

Bar Turbine E

Bladeless Impeller 6 Y

Close Clearance

Impeller and

Stator

Colloid Mill,

Figui