Page 102 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 102

CH AP TER 4 .1 Digital engine control systems

BATTERY EP

PACK DW

POWER

ELECTRONICS AXLE

EP

ICE G EM T/A

HIGH-VOLTAGE

MP BUS MP AXLE

DW

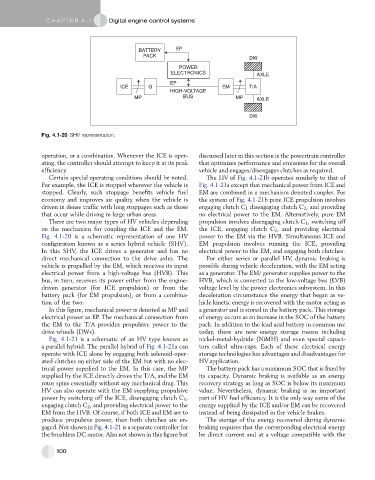

Fig. 4.1-20 SHV representation.

operation, or a combination. Whenever the ICE is oper- discussed later in this section is the powertrain controller

ating, the controller should attempt to keep it at its peak that optimizes performance and emissions for the overall

efficiency. vehicle and engages/disengages clutches as required.

Certain special operating conditions should be noted. The HV of Fig. 4.1-21b operates similarly to that of

For example, the ICE is stopped wherever the vehicle is Fig. 4.1-21a except that mechanical power from ICE and

stopped. Clearly, such stoppage benefits vehicle fuel EM are combined in a mechanism denoted coupler. For

economy and improves air quality when the vehicle is the system of Fig. 4.1-21b pure ICE propulsion involves

driven in dense traffic with long stoppages such as those engaging clutch C 1 disengaging clutch C 2 , and providing

that occur while driving in large urban areas. no electrical power to the EM. Alternatively, pure EM

There are two major types of HV vehicles depending propulsion involves disengaging clutch C 1 , switching off

on the mechanism for coupling the ICE and the EM. the ICE, engaging clutch C 2 , and providing electrical

Fig. 4.1-20 is a schematic representation of one HV power to the EM via the HVB. Simultaneous ICE and

configuration known as a series hybrid vehicle (SHV). EM propulsion involves running the ICE, providing

In this SHV, the ICE drives a generator and has no electrical power to the EM, and engaging both clutches.

direct mechanical connection to the drive axles. The For either series or parallel HV, dynamic braking is

vehicle is propelled by the EM, which receives its input possible during vehicle deceleration, with the EM acting

electrical power from a high-voltage bus (HVB). This as a generator. The EM/ generator supplies power to the

bus, in turn, receives its power either from the engine- HVB, which is converted to the low-voltage bus (LVB)

driven generator (for ICE propulsion) or from the voltage level by the power electronics subsystem. In this

battery pack (for EM propulsion), or from a combina- deceleration circumstance the energy that began as ve-

tion of the two. hicle kinetic energy is recovered with the motor acting as

In this figure, mechanical power is denoted as MP and a generator and is stored in the battery pack. This storage

electrical power as EP. The mechanical connection from of energy occurs as an increase in the SOC of the battery

the EM to the T/A provides propulsive power to the pack. In addition to the lead acid battery in common use

drive wheels (DWs). today, there are new energy storage means including

Fig. 4.1-21 is a schematic of an HV type known as nickel-metal-hydride (NiMH) and even special capaci-

a parallel hybrid. The parallel hybrid of Fig. 4.1-21a can tors called ultra-caps. Each of these electrical energy

operate with ICE alone by engaging both solenoid-oper- storage technologies has advantages and disadvantages for

ated clutches on either side of the EM but with no elec- HV application.

trical power supplied to the EM. In this case, the MP The battery pack has a maximum SOC that is fixed by

supplied by the ICE directly drives the T/A, and the EM its capacity. Dynamic braking is available as an energy

rotor spins essentially without any mechanical drag. This recovery strategy as long as SOC is below its maximum

HV can also operate with the EM supplying propulsive value. Nevertheless, dynamic braking is an important

power by switching off the ICE, disengaging clutch C 1 , part of HV fuel efficiency. It is the only way some of the

engaging clutch C 2 , and providing electrical power to the energy supplied by the ICE and/or EM can be recovered

EM from the HVB. Of course, if both ICE and EM are to instead of being dissipated in the vehicle brakes.

produce propulsive power, then both clutches are en- The storage of the energy recovered during dynamic

gaged. Not shown in Fig. 4.1-21 is a separate controller for braking requires that the corresponding electrical energy

the brushless DC motor. Also not shown in this figure but be direct current and at a voltage compatible with the

100