Page 99 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 99

Digital engine control systems CHAPTER 4.1

concerned with reducing excess emissions during de- integration of the various functions into a single control

celeration, and keeping idle fuel consumption at a mini- unit. Whereas the earlier systems in many cases had

mum. This engine operation is summarized in the separate control systems for fuel and ignition control, the

following list. trend is toward integrated control. This trend has been

made possible, in part, by improvements in digital

1. RPM decreasing rapidly due to driver command or

hardware and in computational algorithms and software.

else held constant at idle.

For example, one of the hardware improvements that has

2. Engine temperature in normal range. been achieved is the operation of the microprocessor unit

3. Air/fuel ratio lean mixture. (MPU) at higher clock frequencies. This higher fre-

4. Special mode in deceleration to reduce emissions. quency results in a reduction of the time for any given

MPU computation, thereby permitting greater compu-

5. Special mode in idle to keep RPM constant at idle as tational capability. This increased computational capa-

load varies due to air conditioner, automatic trans- bility has made it possible, in turn, to have more precise

mission engagement, etc. control of fuel delivery during rapid transient engine

6. EGR on. operation.

7. Secondary air to intake. Except for long steady cruise while driving on certain

rural roads or freeways, the automobile engine is oper-

8. Good fuel economy during deceleration. ated under changing load and RPM conditions. The

9. Poor fuel economy during idle, but fuel consumption limitations in the computational capability of early

kept to minimum possible. engine control systems restricted the ability of the con-

troller to continuously maintain the air/fuel ratio at

4.1.10 Improvements in electronic stoichiometry under such changing operating conditions.

The newer, more capable digital engine control systems

engine control

are more precise than the earlier versions at maintaining

stoichiometry and therefore operate more of the time

The digital engine control system in this chapter has been within the optimum window for the three-way catalytic

made possible by a rapid evolution of the state of tech- converter.

nology. Some of this technology has been briefly men- Moreover, since the control of fuel and ignition re-

tioned in this chapter. It is worthwhile to review some of quires, in some cases, data from the same sensor set, it is

the technological improvements that have occurred in advantageous to have a single integrated system for fuel

digital engine control in greater detail to fully appreciate and ignition timing control. The newer engine controllers

the capabilities of modern digital engine control. have the capability to maintain stoichiometry and si-

multaneously optimize ignition timing.

4.1.10.1 Integrated engine control

system 4.1.10.2 Oxygen sensor improvements

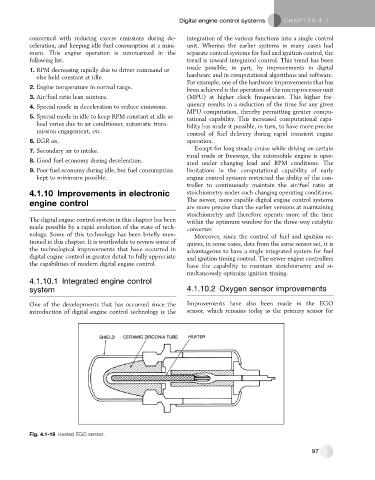

One of the developments that has occurred since the Improvements have also been made in the EGO

introduction of digital engine control technology is the sensor, which remains today as the primary sensor for

Fig. 4.1-18 Heated EGO sensor.

97