Page 103 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 103

Digital engine control systems CHAPTER 4.1

BATTERY EP POWER

PACK LVB ELECTRONICS

(HVB) EP

MP MP

ICE EM T/A

CLUTCH CLUTCH

C

C 1 2

(a)

BATTERY LVB POWER EP

PACK ELECTRONICS HVB EM

DW

C 2 MP

CLUTCH AXLE

ICE COUPLER T/A

MP MP

C AXLE

1

(b) DW

Fig. 4.1-21 Parallel hybrid schematic.

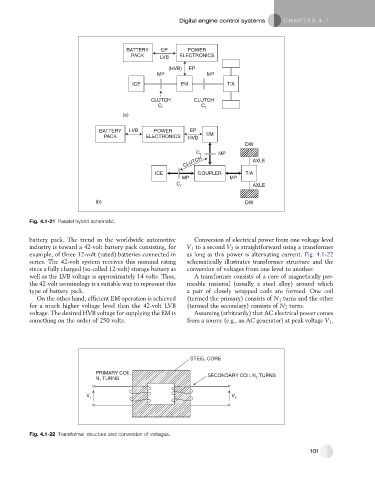

battery pack. The trend in the worldwide automotive Conversion of electrical power from one voltage level

industry is toward a 42-volt battery pack consisting, for V 1 to a second V 2 is straightforward using a transformer

example, of three 12-volt (rated) batteries connected in as long as this power is alternating current. Fig. 4.1-22

series. The 42-volt system receives this nominal rating schematically illustrates transformer structure and the

since a fully charged (so-called 12-volt) storage battery as conversion of voltages from one level to another.

well as the LVB voltage is approximately 14 volts. Thus, A transformer consists of a core of magnetically per-

the 42-volt terminology is a suitable way to represent this meable material (usually a steel alloy) around which

type of battery pack. a pair of closely wrapped coils are formed. One coil

On the other hand, efficient EM operation is achieved (termed the primary) consists of N 1 turns and the other

for a much higher voltage level than the 42-volt LVB (termed the secondary) consists of N 2 turns.

voltage. The desired HVB voltage for supplying the EM is Assuming (arbitrarily) that AC electrical power comes

something on the order of 250 volts. from a source (e.g., an AC generator) at peak voltage V 1 ,

STEEL CORE

PRIMARY COIL SECONDARY COIL N TURNS

N TURNS 2

1

V 1 V 2

Fig. 4.1-22 Transformer structure and conversion of voltages.

101