Page 94 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 94

CH AP TER 4 .1 Digital engine control systems

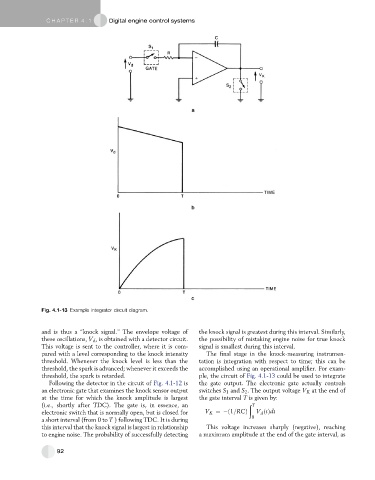

Fig. 4.1-13 Example integrator circuit diagram.

and is thus a ‘‘knock signal.’’ The envelope voltage of the knock signal is greatest during this interval. Similarly,

these oscillations, V d , is obtained with a detector circuit. the possibility of mistaking engine noise for true knock

This voltage is sent to the controller, where it is com- signal is smallest during this interval.

pared with a level corresponding to the knock intensity The final stage in the knock-measuring instrumen-

threshold. Whenever the knock level is less than the tation is integration with respect to time; this can be

threshold, the spark is advanced; whenever it exceeds the accomplished using an operational amplifier. For exam-

threshold, the spark is retarded. ple, the circuit of Fig. 4.1-13 could be used to integrate

Following the detector in the circuit of Fig. 4.1-12 is the gate output. The electronic gate actually controls

an electronic gate that examines the knock sensor output switches S 1 and S 2 . The output voltage V K at the end of

at the time for which the knock amplitude is largest the gate interval T is given by:

(i.e., shortly after TDC). The gate is, in essence, an ð T

electronic switch that is normally open, but is closed for V K ¼ ð1=RCÞ V ðtÞdt

d

a short interval (from 0 to T ) following TDC. It is during 0

this interval that the knock signal is largest in relationship This voltage increases sharply (negative), reaching

to engine noise. The probability of successfully detecting a maximum amplitude at the end of the gate interval, as

92