Page 91 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 91

Digital engine control systems CHAPTER 4.1

ROM LOOK-UP TABLE

MAF

SA S SA P SA T

A/B

POS/RPM

CONTROLLER

D/B

CT

TPS

TRIGGER

ELECTRONIC PULSES DRIVER

IGNITION

CIRCUITRY

SYSTEM

P 1 P 2

SPARK

PLUGS

S 1 S 2

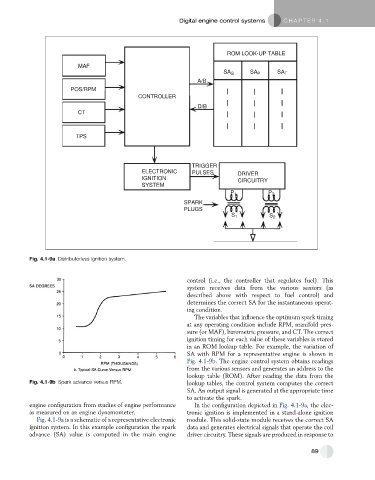

Fig. 4.1-9a Distributorless ignition system.

control (i.e., the controller that regulates fuel). This

system receives data from the various sensors (as

described above with respect to fuel control) and

determines the correct SA for the instantaneous operat-

ing condition.

The variables that influence the optimum spark timing

at any operating condition include RPM, manifold pres-

sure (or MAF), barometric pressure, and CT. The correct

ignition timing for each value of these variables is stored

in an ROM lookup table. For example, the variation of

SA with RPM for a representative engine is shown in

Fig. 4.1-9b. The engine control system obtains readings

from the various sensors and generates an address to the

lookup table (ROM). After reading the data from the

Fig. 4.1-9b Spark advance versus RPM. lookup tables, the control system computes the correct

SA. An output signal is generated at the appropriate time

to activate the spark.

engine configuration from studies of engine performance In the configuration depicted in Fig. 4.1-9a, the elec-

as measured on an engine dynamometer. tronic ignition is implemented in a stand-alone ignition

Fig. 4.1-9a is a schematic of a representative electronic module. This solid-state module receives the correct SA

ignition system. In this example configuration the spark data and generates electrical signals that operate the coil

advance (SA) value is computed in the main engine driver circuitry. These signals are produced in response to

89