Page 135 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 135

Transmissions and driveline CHAPTER 5.1

the corresponding disc surface cannot be travelling at the

same speeds throughout the contact patch.

In Out In Out

In these traction drives both the materials used in the

contact surfaces and the lubricating or traction fluid are

important in giving good reliability and efficiency, ulti-

mately the effectiveness of the transmission. High-grade

Full bearing steels with very low impurity levels have been

toroid

shown by NSK to give the best life in their half-toroidal

variator. Specialfluids havebeendevelopedbyanumberof

companies including Monsanto, and more recently Shell.

In Out In Out

These have given good ‘traction’coefficientsin the order of

0.1 at high pressure whilst retaining good lubrication and

low friction under more normal bearing conditions. It has

also been demonstrated that cleanliness of the fluid is

Half

toroid important in reducing the wear of the rolling components

Lower output speed Higher output speed and hence better filtration than normal is required.

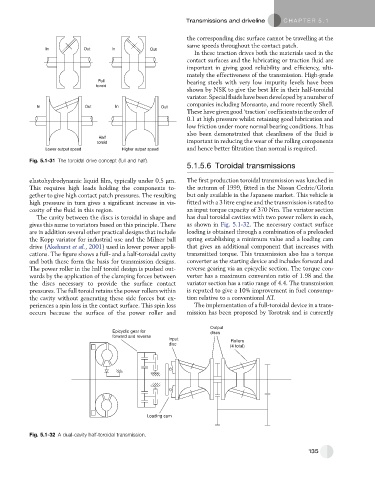

Fig. 5.1-31 The toroidal drive concept (full and half).

5.1.5.6 Toroidal transmissions

elastohydrodynamic liquid film, typically under 0.5 mm. The first production toroidal transmission was lunched in

This requires high loads holding the components to- the autumn of 1999, fitted in the Nissan Cedric/Gloria

gether to give high contact patch pressures. The resulting but only available in the Japanese market. This vehicle is

high pressure in turn gives a significant increase in vis- fitted with a 3 litre engine and the transmission is rated to

cosity of the fluid in this region. an input torque capacity of 370 Nm. The variator section

The cavity between the discs is toroidal in shape and has dual toroidal cavities with two power rollers in each,

gives this name to variators based on this principle. There as shown in Fig. 5.1-32. The necessary contact surface

are in addition several other practical designs that include loading is obtained through a combination of a preloaded

the Kopp variator for industrial use and the Milner ball spring establishing a minimum value and a loading cam

drive (Akehurst et al., 2001) used in lower power appli- that gives an additional component that increases with

cations. The figure shows a full- and a half-toroidal cavity transmitted torque. This transmission also has a torque

and both these form the basis for transmission designs. converter as the starting device and includes forward and

The power roller in the half toroid design is pushed out- reverse gearing via an epicyclic section. The torque con-

wards by the application of the clamping forces between verter has a maximum conversion ratio of 1.98 and the

the discs necessary to provide the surface contact variator section has a ratio range of 4.4. The transmission

pressures. The full toroid retains the power rollers within is reputed to give a 10% improvement in fuel consump-

the cavity without generating these side forces but ex- tion relative to a conventional AT.

periences a spin loss in the contact surface. This spin loss The implementation of a full-toroidal device in a trans-

occurs because the surface of the power roller and mission has been proposed by Torotrak and is currently

Output

Epicyclic gear for discs

forward and reverse

Input

Rollers

disc

(4 total)

Loading cam

Fig. 5.1-32 A dual-cavity half-toroidal transmission.

135