Page 136 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 136

CH AP TER 5 .1 Transmissions and driveline

under development for demonstration in sports utility Unfortunately it cannot then also meet the high

vehicles. This is also a dual cavity with three rollers in each, overdrive ratio that is necessary for good economy and

a front rear layout and rated for 5 Litre engines producing the range needs to be extended through what is called

around 450 Nm torque. In prototype form it has also been a mode change. In high regime the variator output is

fitted to the 2 Litre Ford Mondeo in a front-wheel-drive locked directly to the annulus and transmission output

configuration. This transmission is notable for the use shafts by a multi-plate clutch. At the same time the

of the split path principle to provide an IVTcharacteristic second clutch disconnects the transfer drive input to the

from a CVT variator. carrier of the epicyclic. The change between high and low

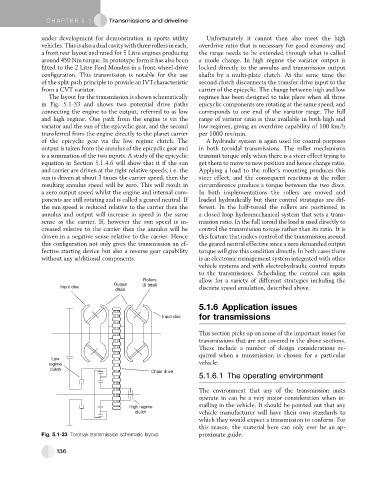

The layout for the transmission is shown schematically regimes has been designed to take place when all three

in Fig. 5.1-33 and shows two potential drive paths epicyclic components are rotating at the same speed, and

connecting the engine to the output, referred to as low corresponds to one end of the variator range. The full

and high regime. One path from the engine is via the range of variator ratio is thus available in both high and

variator and the sun of the epicyclic gear, and the second low regimes, giving an overdrive capability of 100 km/h

transferred from the engine directly to the planet carrier per 1000 rev/min.

of the epicyclic gear via the low regime clutch. The A hydraulic system is again used for control purposes

output is taken from the annulus of the epicyclic gear and in both toroidal transmissions. The roller mechanisms

is a summation of the two inputs. A study of the epicyclic transmit torque only when there is a steer effect trying to

equation in Section 5.1.4.6 will show that it if the sun get them to move to new position and hence change ratio.

and carrier are driven at the right relative speeds, i.e. the Applying a load to the roller’s mounting produces this

sun is driven at about 3 times the carrier speed, then the steer effect, and the consequent reactions at the roller

resulting annulus speed will be zero. This will result in circumference produce a torque between the two discs.

a zero output speed whilst the engine and internal com- In both implementations the rollers are moved and

ponents are still rotating and is called a geared neutral. If loaded hydraulically but their control strategies are dif-

the sun speed is reduced relative to the carrier then the ferent. In the half-toroid the rollers are positioned in

annulus and output will increase in speed in the same a closed loop hydromechanical system that sets a trans-

sense as the carrier. If, however the sun speed is in- mission ratio. In the full toroid the load is used directly to

creased relative to the carrier then the annulus will be control the transmission torque rather than its ratio. It is

driven in a negative sense relative to the carrier. Hence this feature that makes control of the transmission around

this configuration not only gives the transmission an ef- the geared neutral effective since a zero demanded output

fective starting device but also a reverse gear capability torque will give this condition directly. In both cases there

without any additional components. is an electronic management system integrated with other

vehicle systems and with electrohydraulic control inputs

to the transmissions. Scheduling the control can again

Rollers allow for a variety of different strategies including the

Output (6 total)

Input disc discrete speed emulation, described above.

discs

5.1.6 Application issues

Input disc for transmissions

This section picks up on some of the important issues for

transmissions that are not covered in the above sections.

These include a number of design considerations re-

quired when a transmission is chosen for a particular

Low

regime vehicle.

clutch

Chain drive

5.1.6.1 The operating environment

The environment that any of the transmission units

operate in can be a very major consideration when in-

stalling in the vehicle. It should be pointed out that any

High regime

clutch vehicle manufacturer will have their own standards to

which they would expect a transmission to conform. For

this reason, the material here can only ever be an ap-

Fig. 5.1-33 Torotrak transmission schematic layout. proximate guide.

136