Page 15 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 15

Piston-engine cycles of operation CHAPTER 1.1

Fig. 1.1-6 Reverse flow or Schnuerle scavenging.

words, these valves sense the requirements of the

crankcase and so adjust their opening and closing fre-

quencies to match the demands of the engine.

1.1.2.3 Comparison of two- and four-

stroke-cycle petrol engines

The following remarks compare the main points re-

garding the effectiveness of both engine cycles.

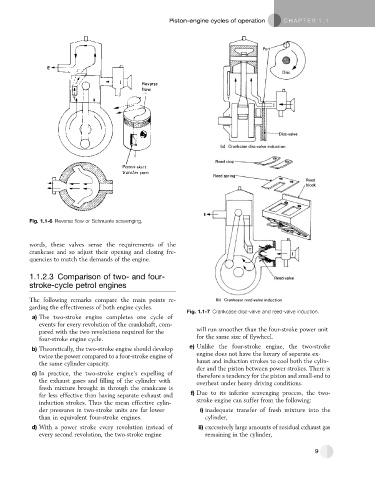

Fig. 1.1-7 Crankcase disc-valve and reed-valve induction.

a) The two-stroke engine completes one cycle of

events for every revolution of the crankshaft, com-

pared with the two revolutions required for the will run smoother than the four-stroke power unit

four-stroke engine cycle. for the same size of flywheel.

b) Theoretically, the two-stroke engine should develop e) Unlike the four-stroke engine, the two-stroke

twice the power compared to a four-stroke engine of engine does not have the luxury of separate ex-

haust and induction strokes to cool both the cylin-

the same cylinder capacity.

der and the piston between power strokes. There is

c) In practice, the two-stroke engine’s expelling of

therefore a tendency for the piston and small-end to

the exhaust gases and filling of the cylinder with

overheat under heavy driving conditions.

fresh mixture brought in through the crankcase is

f) Due to its inferior scavenging process, the two-

far less effective than having separate exhaust and

stroke engine can suffer from the following:

induction strokes. Thus the mean effective cylin-

der pressures in two-stroke units are far lower i) inadequate transfer of fresh mixture into the

than in equivalent four-stroke engines. cylinder,

d) With a power stroke every revolution instead of ii) excessively large amounts of residual exhaust gas

every second revolution, the two-stroke engine remaining in the cylinder,

9