Page 242 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 242

CH AP TER 8 .1 Types of suspension and drive

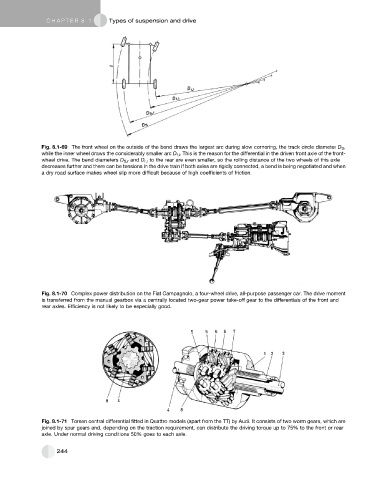

Fig. 8.1-69 The front wheel on the outside of the bend draws the largest arc during slow cornering, the track circle diameter D S ,

while the inner wheel draws the considerably smaller arc D f,i . This is the reason for the differential in the driven front axle of the front-

wheel drive. The bend diameters D S,r and D r,i to the rear are even smaller, so the rolling distance of the two wheels of this axle

decreases further and there can be tensions in the drive train if both axles are rigidly connected, a bend is being negotiated and when

a dry road surface makes wheel slip more difficult because of high coefficients of friction.

Fig. 8.1-70 Complex power distribution on the Fiat Campagnolo, a four-wheel drive, all-purpose passenger car. The drive moment

is transferred from the manual gearbox via a centrally located two-gear power take-off gear to the differentials of the front and

rear axles. Efficiency is not likely to be especially good.

Fig. 8.1-71 Torsen central differential fitted in Quattro models (apart from the TT) by Audi. It consists of two worm gears, which are

joined by spur gears and, depending on the traction requirement, can distribute the driving torque up to 75% to the front or rear

axle. Under normal driving conditions 50% goes to each axle.

244